Omni-Grid® 360

Select another product option

Features

Specifications

Options

Downloads

Features

OMNI-GRID® 360 WELD

BELTS THAT RUN SMOOTHER, STRONGER, LONGER

BELTS THAT RUN SMOOTHER, STRONGER, LONGER

SPIRAL

LOTENSION

HYGENIC

REVOLUTIONARY DESIGN

FOR PARAMOUNT SAFETY

& DURABILITY

REVOLUTIONARY DESIGN FOR PARAMOUNT SAFETY & DURABILITY

The Evolution of Omni-Grid belting continues with the introduction of the 360 Weld on belts that only Ashworth makes. What started as the Omni-Grid is now Omni-Grid 360 where hygiene is built into the belting itself.

The Evolution of Omni-Grid belting continues with the introduction of the 360 Weld on belts that only Ashworth makes. What started as the Omni-Grid is now Omni-Grid 360 where hygiene is built into the belting itself.

INCREASE CAPACITY WHILE MINIMIZING MAINTENANCE COSTS AND DOWNTIME IN YOUR MOST DEMANDING SPIRAL APPLICATIONS WITH OMNI-GRID®

INCREASE CAPACITY WHILE MINIMIZING MAINTENANCE COSTS AND DOWNTIME IN YOUR MOST DEMANDING SPIRAL APPLICATIONS WITH OMNI-GRID®

The Omni-Grid 360 Weld line of belts reduces cage bar wear, maintenance costs and downtime in your most demanding high-tension spiral/turn-curve applications while maintaining belt strength integrity and easy-to-clean/hygienic attributes.

The Omni-Grid 360 Weld line of belts reduces cage bar wear, maintenance costs and downtime in your most demanding high-tension spiral/turn-curve applications while maintaining belt strength integrity and easy-to-clean/hygienic attributes.

HYGIENE BUILT IN

HYGIENE BUILT IN

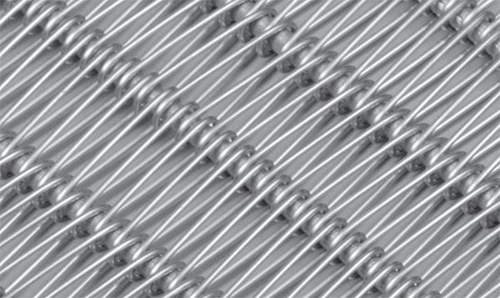

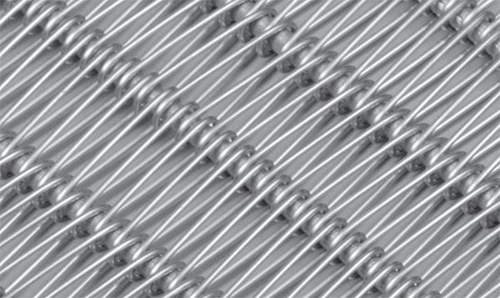

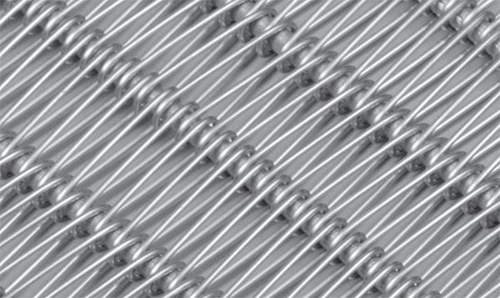

The increased strength of the Omni-Grid® 360 Weld belts comes from the revolutionary 360° buttonless welds utilizing a patented “zero tension” design which:

The increased strength of the Omni-Grid® 360 Weld belts comes from the revolutionary 360° buttonless welds utilizing a patented “zero tension” design which:

Provides higher product load capacity.

Enables smoother running belts.

Creates less wear on spiral system cage bar caps.

Provides higher product load capacity.

Enables smoother running belts.

Creates less wear on spiral system cage bar caps.

Is formed with a proprietary coining process to prevent break-in wear.

Reduces belt elongation.

Increases belt life.

Is formed with a proprietary coining process to prevent break-in wear.

Reduces belt elongation.

Increases belt life.

Standard with the Omni-Tough Mesh Overlay, originally patented by Ashworth.

Increase capacity while minimizing maintenance costs and downtime in your most demanding spiral applications with Omni-Grid® 360 Weld.

Omni-Grid® 360 Weld Link

Competitor Link

WE BUILD-IN HYGIENE WITH THE PATENTED PRECISION WELD

WE BUILD-IN HYGIENE WITH THE PATENTED PRECISION WELD

The patented, zero-tension, 360° buttonless welds eliminate cracking commonly found with traditional bridge welds. Unlike a traditional bridge weld, the 360°buttonless weld is free from surface imperfections and crevices, which improves hygienic characteristics by eliminating the possibility of bacteria entrapments.

The patented, zero-tension, 360° buttonless welds eliminate cracking commonly found with traditional bridge welds. Unlike a traditional bridge weld, the 360°buttonless weld is free from surface imperfections and crevices, which improves hygienic characteristics by eliminating the possibility of bacteria entrapments.

RESISTANT

TO STICKING

IN FREEZER APPLICATIONS

PROVEN RELIABILITY

PROVEN RELIABILITY

All belts are tested and rated for 100,000 cycles versus competitor ratings of only 50,000 cycles. The 1-inch pitch and 1½-inch pitch Omni-Grid® 360 Weld belts are also offered with integral guard-edges with a smooth rounded finish for applications where product retention is a concern. Available in .75-inch, 1-inch, and 1.5-inch pitch, the Omni-Grid 360 Weld belts are the strongest and longest running grid style belts on the market today

All belts are tested and rated for 100,000 cycles versus competitor ratings of only 50,000 cycles. The 1-inch pitch and 1½-inch pitch Omni-Grid® 360 Weld belts are also offered with integral guard-edges with a smooth rounded finish for applications where product retention is a concern. Available in .75-inch, 1-inch, and 1.5-inch pitch, the Omni-Grid 360 Weld belts are the strongest and longest running grid style belts on the market today

STANDARD FEATURES

STANDARD FEATURES

Omni-Tough Mesh Overlay

21/2 times stronger than conventional overlays and is resistant to product sticking in freezer applications.

Pigtail Spirals

Reduces wire breakage.

OPTIONAL FEATURES

OPTIONAL FEATURES

Integral Guard Edges

Now with smooth, rounded edge finish. Durable and easier to clean than modular guard edges. Available for 1 inch and 1.5 inch pitch belts.

Special Mesh Spirals

A cost effective solution for adding land dividers

DIRECTION

APPLICATIONS

PROVEN RELIABILITY

PROVEN RELIABILITY

All belts are tested and rated for 100,000 cycles versus competitor ratings of only 50,000 cycles. The 1-inch pitch and 1½-inch pitch Omni-Grid® 360 Weld belts are also offered with integral guard-edges with a smooth rounded finish for applications where product retention is a concern. Available in .75-inch, 1-inch, and 1.5-inch pitch, the Omni-Grid 360 Weld belts are the strongest and longest running grid style belts on the market today

STANDARD FEATURES

STANDARD FEATURES

Omni-Tough Mesh Overlay

2-1/2 times stronger than conventional overlays and is resistant to product sticking in freezer applications.

Pigtail Spirals

Reduces wire breakage.

OPTIONAL FEATURES

OPTIONAL FEATURES

Integral Guard Edges

Smooth, rounded edge finish. Durable and easier to clean than modular guard edges. Available for 1 inch and 1.5-inch pitch belts.

Special Mesh Spirals

A cost effective solution for adding land dividers

Specifications

Technical Specifications

Select another product option

| Technical Specifications | Units | Omni-Grid® 360 075 |

|---|---|---|

| Turn Ratio | 2.2-6.0 | |

| Pitch | in. [mm] | 0.75 [19.0] |

| Available Widths: Curve/Spiral | in. [mm] | 12-40 (304.8-1016) |

| Available Widths: Straight Run | in. [mm] | 12-60 (304.8-1524.0) |

| Link Height | in. [mm] | 0.44 [11.1] |

| Rod Diameter/Material | in. [mm] | 0.192 (4.9) Metal |

| Conveying Surface | in. [mm] | Width -2.01 [-51.05] |

| Allowable Tension (Curve/Spiral) | lb. [kg] | 150 [68] at 100,000 cycles |

| Allowable Tension (Straight Run) | lb. [kg] | 300 [136] at 100,000 cycles |

| Turn Direction | Bi-directional | |

| Mode of Turning | Inside edge collapses in turn | |

| Method of Drive | Sprockets driven on links |

Available Sprocket Options

Sprocket Reference

Select another sprocket size

Select a product

| Nom. Size | Display | Teeth | Pitch Diameter in (mm) | Hub Diameter in (mm) | Bore Min in (mm) | Bore Max in (mm) |

|---|---|---|---|---|---|---|

| 3 | #3-12 Hardened Steel | 12 | 2.9 (73.66) | 2.36 (59.94) | 1 (25.4) | 1.8 (45.72) |

| 3 | #3-12 Hardened Steel | 12 | 2.9 (73.66) | 2.36 (59.94) | 1 (25.4) | 1.8 (45.72) |

| 3 | #3-12 T303 | 12 | 2.9 (73.66) | 2.36 (59.94) | 1 (25.4) | 1.8 (45.72) |

| 3 | #3-12 T303 | 12 | 2.9 (73.66) | 2.36 (59.94) | 0.94 (23.81) | 1.8 (45.72) |

| 3 | #3-12 UHMW | 12 | 2.9 (73.66) | 2.25 (57.15) | 0 | 1.5 (38.1) |

| 3 | #3-16 UHMW | 16 | 3.84 (97.63) | 3 (76.2) | 1.58 (40.01) | 2.13 (54.1) |

| 3 | #3-16 UHMW | 16 | 3.84 (97.64) | 3 (76.2) | 1 (25.4) | 2.13 (54.1) |

| 4 | #4-17 T303 | 17 | 4.08 (103.68) | 3.58 (90.81) | 0 | 2.83 (71.88) |

| 4 | #4-17 UHMW | 17 | 4.08 (103.68) | 3.58 (90.81) | 0.75 (19.05) | 2.58 (65.53) |

| 4 | #4-17 UHMW | 17 | 4.08 (103.68) | 3.58 (90.81) | 1 (25.4) | 2.58 (65.53) |

| 4 | #4-18 T303 | 18 | 4.32 (109.68) | 3.82 (96.9) | 0 | 2.95 (74.93) |

| 4 | #4-18 T303 | 18 | 4.32 (109.68) | 3.82 (96.9) | 1.58 (40.01) | 2.82 (71.63) |

| 5 | #5-19 UHMW | 19 | 4.56 (115.75) | 4.06 (103.05) | 0.75 (19.05) | 2.94 (74.68) |

| 5 | #5-21 T303 | 21 | 5.03 (127.81) | 4.54 (115.27) | 1 (25.4) | 3.55 (90.17) |

| 5 | #5-21 UHMW | 21 | 5.03 (127.81) | 4.54 (115.27) | 1 (25.4) | 3.42 (86.87) |

| 5 | #5-21 UHMW FS | 21 | 4.79 (121.67) | 4.54 (115.32) | 1 (25.4) | 3.42 (86.87) |

| 6 | #6 UHMW FI | 0 | 0 | 6 (152.4) | 0.75 (19.05) | 4.64 (117.86) |

| 6 | #6 UHMW I | 0 | 0 | 6 (152.4) | 0.75 (19.05) | 4.64 (117.86) |

| 6 | #6-25 T303 | 25 | 5.98 (151.99) | 5.5 (139.67) | 0 | 4.39 (111.51) |

| 6 | #6-25 T303 | 25 | 5.98 (151.99) | 5.5 (139.67) | 0.5 (12.7) | 4.39 (111.51) |

| 6 | #6-25 UHMW | 25 | 5.98 (151.99) | 5.5 (139.67) | 0.88 (22.22) | 4.14 (105.16) |

| 6 | #6-26 T303 | 26 | 6.22 (158.04) | 5.73 (145.64) | 0 | 4.62 (117.35) |

| 6 | #6-26 T303 | 26 | 6.22 (158.04) | 5.73 (145.64) | 1.58 (40.01) | 4.62 (117.35) |

| 6 | #6-26 T303 | 26 | 6.22 (158.04) | 5.73 (145.64) | 1.58 (40.01) | 4.62 (117.35) |

| 6 | #6-26 UHMW | 26 | 6.22 (158.04) | 5.73 (145.64) | 1 (25.4) | 4.37 (111) |

| 6 | #6-27 UHMW | 27 | 6.42 (163.12) | 5.97 (151.61) | 0.88 (22.22) | 4.61 (117.09) |

| 8 | #8-34 UHMW | 34 | 8.13 (206.45) | 7.66 (194.46) | 1 (25.4) | 5.93 (150.62) |

Sprockets available in stainless steel, plain steel, and UHMWPE.

UHMWPE material type components have a 150° F (66°C) maximum operation temperature.

Maximum bore sized listed for UHMWPE material is based on 1/2 inch (12.7 mm) of material above keyway.

*Maximum bores provide adequate material thickness for standard keyway. Specify special sized to be used when necessary.

Supports

Support are required at a minimum of 18" apart on load side and 24" maximum on return side. Rollers may also be used. For light loads, support rails may be placed further apart. Consult Ashworth Engineering for assistance.

Material Reference

- Acetal - polyoxymethylene plastic

- Celcon - acetal copolymer

- CI - cast iron

- Hardened Steel

- Nylon

- T303 - stainless steel

- T316 - stainless steel

- UMHW - polyethylene plastic

Belt Calculator

No Results

Base Belt Weight

Belt Pitch

Turn Ratio

Belt Strength

Min Filler Roll Diameter

Conveying Surface

Inside Conveying Surface

Outside Conveying Surface

Mesh Opening Size

Open Area Surface

Open Area Thru

Need more detailed information?

Need more detailed information?

Need more detailed information?

Options

Product Options

High-Density Mesh Overlay

Traditional grid meshes have double the mesh density at the connecting rods. High density mesh consists of spirals with special intermediate loops to create more product support but at the same time reducing the mesh weight allowing for heavier product loads.

Omni-Tough Mesh Overlay

2½ times stronger than conventional

overlays and is resistant to product

sticking in freezer applications

Patented Pigtail Spirals

Reduces wear breakage

Patented Special Mesh Spirals

A cost effective solution for adding

lane dividers or flights

Does this meet your project needs?

Does this meet your project needs?

Does this meet your project needs?

Let’s get started!

Let’s get started!

Let’s get started!

Downloads

Downloads

Technical Bulletins

Installation, Assembly & Maintenance Instructions

Conveyor System Review Form

Illustrations

-

ROD ONLY OG360 WELD 075

-

B18-16-16 OG360 WELD 075

-

B30-16-16 OG360 WELD 075

-

B36-16-16 OG360 WELD 075

-

B42-16-16 OG360 WELD 075

-

B48-16-16 OG360 WELD 075

-

B54-16-16 OG360 WELD 075

-

B72-16-16 OG360 WELD 075

-

ROD ONLY OG360 WELD 100

-

B18-12-16 OG360 WELD 100

-

B24-12-16 OG360 WELD 100

-

B30-12-16 OG360 WELD 100

-

B36-12-16 OG360 WELD 100

-

B42-12-16 OG360 WELD 100

-

B48-12-16 OG360 WELD 100

-

B54-12-16 OG360 WELD 100

-

B60-12-16 OG360 WELD 100

-

B72-12-16 OG360 WELD 100

-

U48-12-17 OG360 WELD 100

-

U60-12-16 OG360 WELD 100

-

U72-12-16 OG360 WELD 100

-

ROD ONLY OG360 WELD 150

-

B18-8-16 OG360 WELD 150

-

B24-8-16 OG360 WELD 150

-

B24-8-17 OG360 WELD 150 IGE

-

B30-8-16 OG360 WELD 150

-

B36-8-16 OG360 WELD 150

-

B42-8-16 OG360 WELD 150

-

B54-8-16 OG360 WELD 150

-

B72-8-17 OG360 WELD 150

-

U48-8-16 OG360 WELD 150

-

U54-8-17 OG360 WELD 150

-

OG360 100 H96 12 17

-

OG360 100 Rod Only

-

OG360 100 U48 12 17

-

OG360 100 U54 12 16

-

OG360 100 U54 12 17

-

OG360 100 U60 12 16

-

OG360 100 U60 12 17

-

OG360 100 U72 12 16

-

OG360 100 U72 12 17

-

OG360 150 B18 8 16

-

OG360 150 B18 8 17

-

OG360 150 B24 8 16

-

OG360 150 B24 8 17

-

OG360 150 B30 8 16

-

OG360 150 B30 8 17

-

OG360 150 B36 8 16

-

OG360 150 B36 8 17

-

OG360 150 B42 8 16

-

OG360 150 B42 8 17

-

OG360 150 B54 8 16

-

OG360 150 B54 8 17

-

OG360 150 B72 8 17

-

OG360 150 Rod Only

-

OG360 150 U36 8 16

-

OG360 150 U48 8 16

-

OG360 150 U48 8 17

-

OG360 150 U54 8 16

-

OG360 150 U54 8 17

-

OG360 075 B18 16 16

-

OG360 075 B24 16 16

-

OG360 075 B24 16 17

-

OG360 075 B30 16 16

-

OG360 075 B30 16 17

-

OG360 075 B36 16 16

-

OG360 075 B36 16 17

-

OG360 075 B42 16 16

-

OG360 075 B42 16 17

-

OG360 075 B48 16 16

-

OG360 075 B48 16 17

-

OG360 075 B54 16 16

-

OG360 075 B54 16 17

-

OG360 075 B60 16 16

-

OG360 075 B60 16 17

-

OG360 075 B72 16 16

-

OG360 075 B72 16 17

-

OG360 075 H106 16 16

-

OG360 075 H106 16 17

-

OG360 075 H60 16 16

-

OG360 075 H60 16 17

-

OG360 075 H72 16 16

-

OG360 075 H72 16 17

-

OG360 075 H84 16 16

-

OG360 075 H84 16 17

-

OG360 075 H96 16 16

-

OG360 075 H96 16 17

-

OG360 075 NO MESH

-

OG360 075 Rod Only

-

OG360 075 U36 16 16

-

OG360 100 B30 12 17

-

OG360 100 B18 12 16

-

OG360 100 B18 12 17

-

OG360 100 B24 12 16

-

OG360 100 B24 12 17

-

OG360 100 B30 12 16

-

OG360 100 B36 12 16

-

OG360 100 B36 12 17

-

OG360 100 B42 12 16

-

OG360 100 B42 12 17

-

OG360 100 B48 12 16

-

OG360 100 B48 12 17

-

OG360 100 B54 12 16

-

OG360 100 B54 12 17

-

OG360 100 B60 12 16

-

OG360 100 B60 12 17

-

OG360 100 B72 12 16

-

OG360 100 B72 12 17

-

OG360 100 H106 12 16

-

OG360 100 H106 12 17

-

OG360 100 H60 12 16

-

OG360 100 H60 12 17

-

OG360 100 H72 12 16

-

OG360 100 H72 12 17

-

OG360 100 H84 12 16

-

OG360 100 H84 12 17

-

OG360 100 H96 12 16

Features

OMNI-GRID® 360 WELD

BELTS THAT RUN SMOOTHER, STRONGER, LONGER

BELTS THAT RUN SMOOTHER, STRONGER, LONGER

SPIRAL

LOTENSION

HYGENIC

REVOLUTIONARY DESIGN

FOR PARAMOUNT SAFETY

& DURABILITY

REVOLUTIONARY DESIGN FOR PARAMOUNT SAFETY & DURABILITY

The Evolution of Omni-Grid belting continues with the introduction of the 360 Weld on belts that only Ashworth makes. What started as the Omni-Grid is now Omni-Grid 360 where hygiene is built into the belting itself.

The Evolution of Omni-Grid belting continues with the introduction of the 360 Weld on belts that only Ashworth makes. What started as the Omni-Grid is now Omni-Grid 360 where hygiene is built into the belting itself.

INCREASE CAPACITY WHILE MINIMIZING MAINTENANCE COSTS AND DOWNTIME IN YOUR MOST DEMANDING SPIRAL APPLICATIONS WITH OMNI-GRID®

INCREASE CAPACITY WHILE MINIMIZING MAINTENANCE COSTS AND DOWNTIME IN YOUR MOST DEMANDING SPIRAL APPLICATIONS WITH OMNI-GRID®

The Omni-Grid 360 Weld line of belts reduces cage bar wear, maintenance costs and downtime in your most demanding high-tension spiral/turn-curve applications while maintaining belt strength integrity and easy-to-clean/hygienic attributes.

The Omni-Grid 360 Weld line of belts reduces cage bar wear, maintenance costs and downtime in your most demanding high-tension spiral/turn-curve applications while maintaining belt strength integrity and easy-to-clean/hygienic attributes.

HYGIENE BUILT IN

HYGIENE BUILT IN

The increased strength of the Omni-Grid® 360 Weld belts comes from the revolutionary 360° buttonless welds utilizing a patented “zero tension” design which:

The increased strength of the Omni-Grid® 360 Weld belts comes from the revolutionary 360° buttonless welds utilizing a patented “zero tension” design which:

Provides higher product load capacity.

Enables smoother running belts.

Creates less wear on spiral system cage bar caps.

Provides higher product load capacity.

Enables smoother running belts.

Creates less wear on spiral system cage bar caps.

Is formed with a proprietary coining process to prevent break-in wear.

Reduces belt elongation.

Increases belt life.

Is formed with a proprietary coining process to prevent break-in wear.

Reduces belt elongation.

Increases belt life.

Standard with the Omni-Tough Mesh Overlay, originally patented by Ashworth.

Increase capacity while minimizing maintenance costs and downtime in your most demanding spiral applications with Omni-Grid® 360 Weld.

Omni-Grid® 360 Weld Link

Competitor Link

WE BUILD-IN HYGIENE WITH THE PATENTED PRECISION WELD

WE BUILD-IN HYGIENE WITH THE PATENTED PRECISION WELD

The patented, zero-tension, 360° buttonless welds eliminate cracking commonly found with traditional bridge welds. Unlike a traditional bridge weld, the 360°buttonless weld is free from surface imperfections and crevices, which improves hygienic characteristics by eliminating the possibility of bacteria entrapments.

The patented, zero-tension, 360° buttonless welds eliminate cracking commonly found with traditional bridge welds. Unlike a traditional bridge weld, the 360°buttonless weld is free from surface imperfections and crevices, which improves hygienic characteristics by eliminating the possibility of bacteria entrapments.

RESISTANT

TO STICKING

IN FREEZER APPLICATIONS

PROVEN RELIABILITY

PROVEN RELIABILITY

All belts are tested and rated for 100,000 cycles versus competitor ratings of only 50,000 cycles. The 1-inch pitch and 1½-inch pitch Omni-Grid® 360 Weld belts are also offered with integral guard-edges with a smooth rounded finish for applications where product retention is a concern. Available in .75-inch, 1-inch, and 1.5-inch pitch, the Omni-Grid 360 Weld belts are the strongest and longest running grid style belts on the market today

All belts are tested and rated for 100,000 cycles versus competitor ratings of only 50,000 cycles. The 1-inch pitch and 1½-inch pitch Omni-Grid® 360 Weld belts are also offered with integral guard-edges with a smooth rounded finish for applications where product retention is a concern. Available in .75-inch, 1-inch, and 1.5-inch pitch, the Omni-Grid 360 Weld belts are the strongest and longest running grid style belts on the market today

STANDARD FEATURES

STANDARD FEATURES

Omni-Tough Mesh Overlay

21/2 times stronger than conventional overlays and is resistant to product sticking in freezer applications.

Pigtail Spirals

Reduces wire breakage.

OPTIONAL FEATURES

OPTIONAL FEATURES

Integral Guard Edges

Now with smooth, rounded edge finish. Durable and easier to clean than modular guard edges. Available for 1 inch and 1.5 inch pitch belts.

Special Mesh Spirals

A cost effective solution for adding land dividers

DIRECTION

APPLICATIONS

PROVEN RELIABILITY

PROVEN RELIABILITY

All belts are tested and rated for 100,000 cycles versus competitor ratings of only 50,000 cycles. The 1-inch pitch and 1½-inch pitch Omni-Grid® 360 Weld belts are also offered with integral guard-edges with a smooth rounded finish for applications where product retention is a concern. Available in .75-inch, 1-inch, and 1.5-inch pitch, the Omni-Grid 360 Weld belts are the strongest and longest running grid style belts on the market today

STANDARD FEATURES

STANDARD FEATURES

Omni-Tough Mesh Overlay

2-1/2 times stronger than conventional overlays and is resistant to product sticking in freezer applications.

Pigtail Spirals

Reduces wire breakage.

OPTIONAL FEATURES

OPTIONAL FEATURES

Integral Guard Edges

Smooth, rounded edge finish. Durable and easier to clean than modular guard edges. Available for 1 inch and 1.5-inch pitch belts.

Special Mesh Spirals

A cost effective solution for adding land dividers

Specifications

Technical Specifications

Select another product option

| Technical Specifications | Units | Omni-Grid® 360 100 |

|---|---|---|

| Turn Ratio | 1.7-6.0 | |

| Pitch | in. [mm] | 1.08 [27.4] |

| Available Widths: Curve/Spiral | in. [mm] | 12-40 (304.8-1016) |

| Available Widths: Straight Run | in. [mm] | 12-48 (304.8-1219.2) |

| Link Height | in. [mm] | 0.50 [12.7] |

| Rod Diameter/Material | in. [mm] | 0.192 (4.9) Metal |

| Conveying Surface | in. [mm] | Width -2.53 [-64.26] |

| Allowable Tension (Curve/Spiral) | lb. [kg] | 200 [91] at 100,000 cycles |

| Allowable Tension (Straight Run) | lb. [kg] | 400 [181] at 100,000 cycles |

| Turn Direction | Bi-directional | |

| Mode of Turning | Inside edge collapses in turn | |

| Method of Drive | Sprockets driven on links |

Available Sprocket Options

Sprocket Reference

Select another sprocket size

Select a product

| Nom. Size | Display | Teeth | Pitch Diameter in (mm) | Hub Diameter in (mm) | Bore Min in (mm) | Bore Max in (mm) |

|---|---|---|---|---|---|---|

| 3 | #3-9 Hardened Steel | 9 | 0 | 2.45 (62.23) | 1 (25.4) | 1.83 (46.48) |

| 3 | #3-9 T303 | 9 | 3.16 (80.26) | 2.46 (62.48) | 1 (25.4) | 1.84 (46.74) |

| 3 | #3-9 T303 | 9 | 3.16 (80.26) | 2.46 (62.48) | 1 (25.4) | 1.84 (46.74) |

| 3 | #3-9 T303 | 9 | 3.16 (80.26) | 2.46 (62.48) | 1.25 (31.75) | 1.84 (46.74) |

| 3 | #3-9 T303 | 9 | 3.16 (80.26) | 2.46 (62.48) | 0.94 (23.81) | 1.84 (46.74) |

| 3 | #3-9 T316 | 9 | 3.16 (80.26) | 2.46 (62.48) | 1.44 (36.51) | 1.84 (46.74) |

| 3 | #3-9 UHMW | 9 | 3.16 (80.26) | 2.53 (64.26) | 1 (25.4) | 1.72 (43.69) |

| 3 | #3-9 UHMW | 9 | 3.16 (80.26) | 2.53 (64.26) | 0 | 1.72 (43.69) |

| 4 | #4 UHMW FI | 0 | 0 | 3.92 (99.57) | 0.75 (19.05) | 2.93 (74.42) |

| 4 | #4 UHMW I | 0 | 0 | 3.92 (99.57) | 0 | 2.93 (74.42) |

| 4 | #4-11 T303 | 11 | 3.83 (97.36) | 3.18 (80.72) | 0 | 2.07 (52.58) |

| 4 | #4-11 T303 | 11 | 3.83 (97.36) | 3.18 (80.72) | 0 | 2.44 (61.98) |

| 4 | #4-12 T303 | 12 | 4.17 (105.97) | 3.54 (89.92) | 0 | 2.8 (71.12) |

| 4 | #4-12 T316 | 12 | 4.17 (105.97) | 3.54 (89.92) | 0 | 2.8 (71.12) |

| 4 | #4-12 UHMW | 12 | 4.17 (105.97) | 3.45 (87.63) | 0.75 (19.05) | 2.46 (62.48) |

| 4 | #4-13 Celcon | 13 | 4.4 (111.76) | 3.9 (99.06) | 1 (25.4) | 2.91 (73.91) |

| 4 | #4-13 CI | 13 | 4.53 (115.09) | 3.91 (99.22) | 0 | 3.04 (77.22) |

| 4 | #4-13 T316 | 13 | 4.53 (115.09) | 3.91 (99.22) | 0 | 3.04 (77.22) |

| 4 | #4-13 UHMW | 13 | 4.53 (115.06) | 3.9 (99.06) | 1 (25.4) | 2.91 (73.91) |

| 5 | #5-15 T303 | 15 | 5.2 (131.95) | 4.58 (116.36) | 0 | 3.59 (91.19) |

| 5 | #5-15 UHMW | 15 | 5.2 (131.95) | 4.58 (116.36) | 2 (50.8) | 3.46 (87.88) |

| 6 | #6 UHMW FI | 0 | 0 | 5.65 (143.51) | 0.75 (19.05) | 4.29 (108.97) |

| 6 | #6 UHMW I | 0 | 0 | 5.65 (143.51) | 0 | 4.29 (108.97) |

| 6 | #6-18 CI | 18 | 6.24 (158.5) | 5.66 (143.67) | 0 | 3.75 (95.25) |

| 6 | #6-18 Nylon | 18 | 6.24 (158.5) | 5.65 (143.51) | 1 (25.4) | 4.54 (115.32) |

| 6 | #6-18 T316 | 18 | 6.24 (158.5) | 5.66 (143.67) | 1 (25.4) | 3.75 (95.25) |

| 6 | #6-18 UHMW | 18 | 6.24 (158.5) | 5.65 (143.51) | 0 | 4.29 (108.97) |

| 6 | #6-18 UHMW FS | 18 | 6.15 (156.16) | 5.65 (143.46) | 0 | 4.29 (108.97) |

| 6 | #6-18 UHMW Product Release | 18 | 6.4 (162.51) | 5.65 (143.46) | 1 (25.4) | 4.29 (108.97) |

| 6 | #6-18 UHMW Split | 18 | 6.24 (158.5) | 5.65 (143.46) | 0 | 4.29 (108.97) |

| 6 | #6-19 T303 | 19 | 6.55 (166.47) | 6.03 (153.21) | 0 | 4.8 (121.92) |

| 6 | #6-19 UHMW | 19 | 6.55 (166.47) | 6.03 (153.21) | 1.18 (30) | 4.67 (118.62) |

| 8 | #8 UHMW FI | 0 | 0 | 7.38 (187.45) | 0.75 (19.05) | 5.89 (149.61) |

| 8 | #8 UHMW I | 0 | 0 | 7.38 (187.45) | 0 | 5.89 (149.61) |

| 8 | #8-23 CI | 23 | 7.41 (188.11) | 7.41 (188.11) | 0 | 5.9 (149.86) |

| 8 | #8-23 CI | 23 | 7.96 (202.18) | 7.41 (188.12) | 0 | 4.75 (120.65) |

| 8 | #8-23 T316 | 23 | 7.96 (202.18) | 7.41 (188.12) | 0 | 4.75 (120.65) |

| 8 | #8-23 T316 | 23 | 7.97 (202.41) | 7.41 (188.12) | 1 (25.4) | 4.75 (120.65) |

| 8 | #8-23 UHMW | 23 | 7.96 (202.18) | 7.39 (187.71) | 1 (25.4) | 5.9 (149.86) |

| 8 | #8-23 UHMW Split | 23 | 7.89 (200.33) | 7.39 (187.63) | 0 | 5.9 (149.86) |

| 10 | #10-31 CI | 31 | 10.72 (272.29) | 10.16 (258.06) | 0 | 8.67 (220.22) |

| 10 | #10-31 T316 | 31 | 10.72 (272.29) | 10.16 (258.06) | 0 | 8.67 (220.22) |

| 10 | #10-31 UHMW | 31 | 10.66 (270.76) | 10.16 (258.06) | 0.99 (25.02) | 8.42 (213.87) |

| 12 | #12-37 UHMW | 37 | 12.74 (323.49) | 12.24 (310.79) | 0.99 (25.02) | 10.49 (266.45) |

UHMWPE material type components have a 150° F (66°C) maximum operation temperature.

Maximum bore sized listed for UHMWPE material is based on 1/2 inch (12.7 mm) of material above keyway.

Supports

Support are required at a minimum of 18" apart on load side and 24" maximum on return side. Rollers may also be used. For light loads, support rails may be placed further apart. Consult Ashworth Engineering for assistance.

Material Reference

- Acetal - polyoxymethylene plastic

- Celcon - acetal copolymer

- CI - cast iron

- Hardened Steel

- Nylon

- T303 - stainless steel

- T316 - stainless steel

- UMHW - polyethylene plastic

Belt Calculator

No Results

Base Belt Weight

Belt Pitch

Turn Ratio

Belt Strength

Min Filler Roll Diameter

Conveying Surface

Inside Conveying Surface

Outside Conveying Surface

Mesh Opening Size

Open Area Surface

Open Area Thru

Need more detailed information?

Need more detailed information?

Need more detailed information?

Options

Product Options

High-Density Mesh Overlay

Traditional grid meshes have double the mesh density at the connecting rods. High density mesh consists of spirals with special intermediate loops to create more product support but at the same time reducing the mesh weight allowing for heavier product loads.

Omni-Tough Mesh Overlay

2½ times stronger than conventional

overlays and is resistant to product

sticking in freezer applications

Patented Pigtail Spirals

Reduces wear breakage

Patented Special Mesh Spirals

A cost effective solution for adding

lane dividers or flights

Does this meet your project needs?

Does this meet your project needs?

Does this meet your project needs?

Let’s get started!

Let’s get started!

Let’s get started!

Downloads

Downloads

Technical Bulletins

Installation, Assembly & Maintenance Instructions

Conveyor System Review Form

Illustrations

-

ROD ONLY OG360 WELD 075

-

B18-16-16 OG360 WELD 075

-

B30-16-16 OG360 WELD 075

-

B36-16-16 OG360 WELD 075

-

B42-16-16 OG360 WELD 075

-

B48-16-16 OG360 WELD 075

-

B54-16-16 OG360 WELD 075

-

B72-16-16 OG360 WELD 075

-

ROD ONLY OG360 WELD 100

-

B18-12-16 OG360 WELD 100

-

B24-12-16 OG360 WELD 100

-

B30-12-16 OG360 WELD 100

-

B36-12-16 OG360 WELD 100

-

B42-12-16 OG360 WELD 100

-

B48-12-16 OG360 WELD 100

-

B54-12-16 OG360 WELD 100

-

B60-12-16 OG360 WELD 100

-

B72-12-16 OG360 WELD 100

-

U48-12-17 OG360 WELD 100

-

U60-12-16 OG360 WELD 100

-

U72-12-16 OG360 WELD 100

-

ROD ONLY OG360 WELD 150

-

B18-8-16 OG360 WELD 150

-

B24-8-16 OG360 WELD 150

-

B24-8-17 OG360 WELD 150 IGE

-

B30-8-16 OG360 WELD 150

-

B36-8-16 OG360 WELD 150

-

B42-8-16 OG360 WELD 150

-

B54-8-16 OG360 WELD 150

-

B72-8-17 OG360 WELD 150

-

U48-8-16 OG360 WELD 150

-

U54-8-17 OG360 WELD 150

-

OG360 100 H96 12 17

-

OG360 100 Rod Only

-

OG360 100 U48 12 17

-

OG360 100 U54 12 16

-

OG360 100 U54 12 17

-

OG360 100 U60 12 16

-

OG360 100 U60 12 17

-

OG360 100 U72 12 16

-

OG360 100 U72 12 17

-

OG360 150 B18 8 16

-

OG360 150 B18 8 17

-

OG360 150 B24 8 16

-

OG360 150 B24 8 17

-

OG360 150 B30 8 16

-

OG360 150 B30 8 17

-

OG360 150 B36 8 16

-

OG360 150 B36 8 17

-

OG360 150 B42 8 16

-

OG360 150 B42 8 17

-

OG360 150 B54 8 16

-

OG360 150 B54 8 17

-

OG360 150 B72 8 17

-

OG360 150 Rod Only

-

OG360 150 U36 8 16

-

OG360 150 U48 8 16

-

OG360 150 U48 8 17

-

OG360 150 U54 8 16

-

OG360 150 U54 8 17

-

OG360 075 B18 16 16

-

OG360 075 B24 16 16

-

OG360 075 B24 16 17

-

OG360 075 B30 16 16

-

OG360 075 B30 16 17

-

OG360 075 B36 16 16

-

OG360 075 B36 16 17

-

OG360 075 B42 16 16

-

OG360 075 B42 16 17

-

OG360 075 B48 16 16

-

OG360 075 B48 16 17

-

OG360 075 B54 16 16

-

OG360 075 B54 16 17

-

OG360 075 B60 16 16

-

OG360 075 B60 16 17

-

OG360 075 B72 16 16

-

OG360 075 B72 16 17

-

OG360 075 H106 16 16

-

OG360 075 H106 16 17

-

OG360 075 H60 16 16

-

OG360 075 H60 16 17

-

OG360 075 H72 16 16

-

OG360 075 H72 16 17

-

OG360 075 H84 16 16

-

OG360 075 H84 16 17

-

OG360 075 H96 16 16

-

OG360 075 H96 16 17

-

OG360 075 NO MESH

-

OG360 075 Rod Only

-

OG360 075 U36 16 16

-

OG360 100 B30 12 17

-

OG360 100 B18 12 16

-

OG360 100 B18 12 17

-

OG360 100 B24 12 16

-

OG360 100 B24 12 17

-

OG360 100 B30 12 16

-

OG360 100 B36 12 16

-

OG360 100 B36 12 17

-

OG360 100 B42 12 16

-

OG360 100 B42 12 17

-

OG360 100 B48 12 16

-

OG360 100 B48 12 17

-

OG360 100 B54 12 16

-

OG360 100 B54 12 17

-

OG360 100 B60 12 16

-

OG360 100 B60 12 17

-

OG360 100 B72 12 16

-

OG360 100 B72 12 17

-

OG360 100 H106 12 16

-

OG360 100 H106 12 17

-

OG360 100 H60 12 16

-

OG360 100 H60 12 17

-

OG360 100 H72 12 16

-

OG360 100 H72 12 17

-

OG360 100 H84 12 16

-

OG360 100 H84 12 17

-

OG360 100 H96 12 16

Features

OMNI-GRID® 360 WELD

BELTS THAT RUN SMOOTHER, STRONGER, LONGER

BELTS THAT RUN SMOOTHER, STRONGER, LONGER

SPIRAL

LOTENSION

HYGENIC

REVOLUTIONARY DESIGN

FOR PARAMOUNT SAFETY

& DURABILITY

REVOLUTIONARY DESIGN FOR PARAMOUNT SAFETY & DURABILITY

The Evolution of Omni-Grid belting continues with the introduction of the 360 Weld on belts that only Ashworth makes. What started as the Omni-Grid is now Omni-Grid 360 where hygiene is built into the belting itself.

The Evolution of Omni-Grid belting continues with the introduction of the 360 Weld on belts that only Ashworth makes. What started as the Omni-Grid is now Omni-Grid 360 where hygiene is built into the belting itself.

INCREASE CAPACITY WHILE MINIMIZING MAINTENANCE COSTS AND DOWNTIME IN YOUR MOST DEMANDING SPIRAL APPLICATIONS WITH OMNI-GRID®

INCREASE CAPACITY WHILE MINIMIZING MAINTENANCE COSTS AND DOWNTIME IN YOUR MOST DEMANDING SPIRAL APPLICATIONS WITH OMNI-GRID®

The Omni-Grid 360 Weld line of belts reduces cage bar wear, maintenance costs and downtime in your most demanding high-tension spiral/turn-curve applications while maintaining belt strength integrity and easy-to-clean/hygienic attributes.

The Omni-Grid 360 Weld line of belts reduces cage bar wear, maintenance costs and downtime in your most demanding high-tension spiral/turn-curve applications while maintaining belt strength integrity and easy-to-clean/hygienic attributes.

HYGIENE BUILT IN

HYGIENE BUILT IN

The increased strength of the Omni-Grid® 360 Weld belts comes from the revolutionary 360° buttonless welds utilizing a patented “zero tension” design which:

The increased strength of the Omni-Grid® 360 Weld belts comes from the revolutionary 360° buttonless welds utilizing a patented “zero tension” design which:

Provides higher product load capacity.

Enables smoother running belts.

Creates less wear on spiral system cage bar caps.

Provides higher product load capacity.

Enables smoother running belts.

Creates less wear on spiral system cage bar caps.

Is formed with a proprietary coining process to prevent break-in wear.

Reduces belt elongation.

Increases belt life.

Is formed with a proprietary coining process to prevent break-in wear.

Reduces belt elongation.

Increases belt life.

Standard with the Omni-Tough Mesh Overlay, originally patented by Ashworth.

Increase capacity while minimizing maintenance costs and downtime in your most demanding spiral applications with Omni-Grid® 360 Weld.

Omni-Grid® 360 Weld Link

Competitor Link

WE BUILD-IN HYGIENE WITH THE PATENTED PRECISION WELD

WE BUILD-IN HYGIENE WITH THE PATENTED PRECISION WELD

The patented, zero-tension, 360° buttonless welds eliminate cracking commonly found with traditional bridge welds. Unlike a traditional bridge weld, the 360°buttonless weld is free from surface imperfections and crevices, which improves hygienic characteristics by eliminating the possibility of bacteria entrapments.

The patented, zero-tension, 360° buttonless welds eliminate cracking commonly found with traditional bridge welds. Unlike a traditional bridge weld, the 360°buttonless weld is free from surface imperfections and crevices, which improves hygienic characteristics by eliminating the possibility of bacteria entrapments.

RESISTANT

TO STICKING

IN FREEZER APPLICATIONS

PROVEN RELIABILITY

PROVEN RELIABILITY

All belts are tested and rated for 100,000 cycles versus competitor ratings of only 50,000 cycles. The 1-inch pitch and 1½-inch pitch Omni-Grid® 360 Weld belts are also offered with integral guard-edges with a smooth rounded finish for applications where product retention is a concern. Available in .75-inch, 1-inch, and 1.5-inch pitch, the Omni-Grid 360 Weld belts are the strongest and longest running grid style belts on the market today

All belts are tested and rated for 100,000 cycles versus competitor ratings of only 50,000 cycles. The 1-inch pitch and 1½-inch pitch Omni-Grid® 360 Weld belts are also offered with integral guard-edges with a smooth rounded finish for applications where product retention is a concern. Available in .75-inch, 1-inch, and 1.5-inch pitch, the Omni-Grid 360 Weld belts are the strongest and longest running grid style belts on the market today

STANDARD FEATURES

STANDARD FEATURES

Omni-Tough Mesh Overlay

21/2 times stronger than conventional overlays and is resistant to product sticking in freezer applications.

Pigtail Spirals

Reduces wire breakage.

OPTIONAL FEATURES

OPTIONAL FEATURES

Integral Guard Edges

Now with smooth, rounded edge finish. Durable and easier to clean than modular guard edges. Available for 1 inch and 1.5 inch pitch belts.

Special Mesh Spirals

A cost effective solution for adding land dividers

DIRECTION

APPLICATIONS

PROVEN RELIABILITY

PROVEN RELIABILITY

All belts are tested and rated for 100,000 cycles versus competitor ratings of only 50,000 cycles. The 1-inch pitch and 1½-inch pitch Omni-Grid® 360 Weld belts are also offered with integral guard-edges with a smooth rounded finish for applications where product retention is a concern. Available in .75-inch, 1-inch, and 1.5-inch pitch, the Omni-Grid 360 Weld belts are the strongest and longest running grid style belts on the market today

STANDARD FEATURES

STANDARD FEATURES

Omni-Tough Mesh Overlay

2-1/2 times stronger than conventional overlays and is resistant to product sticking in freezer applications.

Pigtail Spirals

Reduces wire breakage.

OPTIONAL FEATURES

OPTIONAL FEATURES

Integral Guard Edges

Smooth, rounded edge finish. Durable and easier to clean than modular guard edges. Available for 1 inch and 1.5-inch pitch belts.

Special Mesh Spirals

A cost effective solution for adding land dividers

Specifications

Technical Specifications

Select another product option

| Technical Specifications | Units | Omni-Grid® 360 150 |

|---|---|---|

| Turn Ratio | 1.6-6.0 | |

| Pitch | in. [mm] | 1.50 [38.1] |

| Available Widths: Curve/Spiral | in. [mm] | 12-54 (304.8-1372) |

| Available Widths: Straight Run | in. [mm] | 12-60 (304.8-1524.0) |

| Link Height | in. [mm] | 0.59 [15.0] |

| Rod Diameter/Material | in. [mm] | 0.236 (6.0) Metal |

| Conveying Surface | in. [mm] | Width -2.94 [-74.68] |

| Allowable Tension (Curve/Spiral) | lb. [kg] | 400 [181] at 100,000 cycles |

| Allowable Tension (Straight Run) | lb. [kg] | 800 [363] at 100,000 cycles |

| Turn Direction | Bi-directional | |

| Mode of Turning | Inside edge collapses in turn | |

| Method of Drive | Sprockets driven on links |

Available Sprocket Options

Sprocket Reference

Select another sprocket size

Select a product

| Nom. Size | Display | Teeth | Pitch Diameter in (mm) | Hub Diameter in (mm) | Bore Min in (mm) | Bore Max in (mm) |

|---|---|---|---|---|---|---|

| 6 | #6 UHMW FI | 0 | 0 | 5.5 (139.7) | 0.75 (19.05) | 4.14 (105.16) |

| 6 | #6 UHMW I | 0 | 0 | 5.5 (139.7) | 0.75 (19.05) | 4.14 (105.16) |

| 6 | #6-13 UHMW Not Recommended | 13 | 6.27 (159.26) | 5.5 (139.7) | 0 | 4.14 (105.16) |

| 8 | #8 UHMW FI | 0 | 0 | 7.43 (188.72) | 0 | 5.94 (150.88) |

| 8 | #8 UHMW I | 0 | 0 | 7.43 (188.72) | 0.75 (19.05) | 5.94 (150.88) |

| 8 | #8-17 T303 | 17 | 8.16 (207.26) | 7.43 (188.72) | 0 | 5.95 (151.13) |

| 8 | #8-17 UHMW | 17 | 8.16 (207.26) | 7.43 (188.72) | 0.75 (19.05) | 5.94 (150.88) |

UHMWPE material type components have a 150° F (66°C) maximum operation temperature.

Maximum bore sized listed for UHMWPE material is based on 1/2 inch (12.7 mm) of material above keyway.

Supports

Supports are required at a minimum of 18" apart on load side and 24" maximum on return side. Rollers may also be used. For light loads, support rails may be placed further apart. Consult Ashworth Engineering for assistance.

Material Reference

- Acetal - polyoxymethylene plastic

- Celcon - acetal copolymer

- CI - cast iron

- Hardened Steel

- Nylon

- T303 - stainless steel

- T316 - stainless steel

- UMHW - polyethylene plastic

Belt Calculator

No Results

Base Belt Weight

Belt Pitch

Turn Ratio

Belt Strength

Min Filler Roll Diameter

Conveying Surface

Inside Conveying Surface

Outside Conveying Surface

Mesh Opening Size

Open Area Surface

Open Area Thru

Need more detailed information?

Need more detailed information?

Need more detailed information?

Options

Product Options

High-Density Mesh Overlay

Traditional grid meshes have double the mesh density at the connecting rods. High density mesh consists of spirals with special intermediate loops to create more product support but at the same time reducing the mesh weight allowing for heavier product loads.

Omni-Tough Mesh Overlay

2½ times stronger than conventional

overlays and is resistant to product

sticking in freezer applications

Patented Pigtail Spirals

Reduces wear breakage

Patented Special Mesh Spirals

A cost effective solution for adding

lane dividers or flights

Does this meet your project needs?

Does this meet your project needs?

Does this meet your project needs?

Let’s get started!

Let’s get started!

Let’s get started!

Downloads

Downloads

Technical Bulletins

Installation, Assembly & Maintenance Instructions

Conveyor System Review Form

Illustrations

-

ROD ONLY OG360 WELD 075

-

B18-16-16 OG360 WELD 075

-

B30-16-16 OG360 WELD 075

-

B36-16-16 OG360 WELD 075

-

B42-16-16 OG360 WELD 075

-

B48-16-16 OG360 WELD 075

-

B54-16-16 OG360 WELD 075

-

B72-16-16 OG360 WELD 075

-

ROD ONLY OG360 WELD 100

-

B18-12-16 OG360 WELD 100

-

B24-12-16 OG360 WELD 100

-

B30-12-16 OG360 WELD 100

-

B36-12-16 OG360 WELD 100

-

B42-12-16 OG360 WELD 100

-

B48-12-16 OG360 WELD 100

-

B54-12-16 OG360 WELD 100

-

B60-12-16 OG360 WELD 100

-

B72-12-16 OG360 WELD 100

-

U48-12-17 OG360 WELD 100

-

U60-12-16 OG360 WELD 100

-

U72-12-16 OG360 WELD 100

-

ROD ONLY OG360 WELD 150

-

B18-8-16 OG360 WELD 150

-

B24-8-16 OG360 WELD 150

-

B24-8-17 OG360 WELD 150 IGE

-

B30-8-16 OG360 WELD 150

-

B36-8-16 OG360 WELD 150

-

B42-8-16 OG360 WELD 150

-

B54-8-16 OG360 WELD 150

-

B72-8-17 OG360 WELD 150

-

U48-8-16 OG360 WELD 150

-

U54-8-17 OG360 WELD 150

-

OG360 100 H96 12 17

-

OG360 100 Rod Only

-

OG360 100 U48 12 17

-

OG360 100 U54 12 16

-

OG360 100 U54 12 17

-

OG360 100 U60 12 16

-

OG360 100 U60 12 17

-

OG360 100 U72 12 16

-

OG360 100 U72 12 17

-

OG360 150 B18 8 16

-

OG360 150 B18 8 17

-

OG360 150 B24 8 16

-

OG360 150 B24 8 17

-

OG360 150 B30 8 16

-

OG360 150 B30 8 17

-

OG360 150 B36 8 16

-

OG360 150 B36 8 17

-

OG360 150 B42 8 16

-

OG360 150 B42 8 17

-

OG360 150 B54 8 16

-

OG360 150 B54 8 17

-

OG360 150 B72 8 17

-

OG360 150 Rod Only

-

OG360 150 U36 8 16

-

OG360 150 U48 8 16

-

OG360 150 U48 8 17

-

OG360 150 U54 8 16

-

OG360 150 U54 8 17

-

OG360 075 B18 16 16

-

OG360 075 B24 16 16

-

OG360 075 B24 16 17

-

OG360 075 B30 16 16

-

OG360 075 B30 16 17

-

OG360 075 B36 16 16

-

OG360 075 B36 16 17

-

OG360 075 B42 16 16

-

OG360 075 B42 16 17

-

OG360 075 B48 16 16

-

OG360 075 B48 16 17

-

OG360 075 B54 16 16

-

OG360 075 B54 16 17

-

OG360 075 B60 16 16

-

OG360 075 B60 16 17

-

OG360 075 B72 16 16

-

OG360 075 B72 16 17

-

OG360 075 H106 16 16

-

OG360 075 H106 16 17

-

OG360 075 H60 16 16

-

OG360 075 H60 16 17

-

OG360 075 H72 16 16

-

OG360 075 H72 16 17

-

OG360 075 H84 16 16

-

OG360 075 H84 16 17

-

OG360 075 H96 16 16

-

OG360 075 H96 16 17

-

OG360 075 NO MESH

-

OG360 075 Rod Only

-

OG360 075 U36 16 16

-

OG360 100 B30 12 17

-

OG360 100 B18 12 16

-

OG360 100 B18 12 17

-

OG360 100 B24 12 16

-

OG360 100 B24 12 17

-

OG360 100 B30 12 16

-

OG360 100 B36 12 16

-

OG360 100 B36 12 17

-

OG360 100 B42 12 16

-

OG360 100 B42 12 17

-

OG360 100 B48 12 16

-

OG360 100 B48 12 17

-

OG360 100 B54 12 16

-

OG360 100 B54 12 17

-

OG360 100 B60 12 16

-

OG360 100 B60 12 17

-

OG360 100 B72 12 16

-

OG360 100 B72 12 17

-

OG360 100 H106 12 16

-

OG360 100 H106 12 17

-

OG360 100 H60 12 16

-

OG360 100 H60 12 17

-

OG360 100 H72 12 16

-

OG360 100 H72 12 17

-

OG360 100 H84 12 16

-

OG360 100 H84 12 17

-

OG360 100 H96 12 16

Features

SMALL RADIUS OMNI-GRID® 360 75 WELD

BELTS THAT RUN SMOOTHER, STRONGER, LONGER

BELTS THAT RUN SMOOTHER, STRONGER, LONGER

SPIRAL

LOTENSION

HYGENIC

TIGHT, 1.1 TURN RATIO FOR SMALL FOOTPRINT OPERATIONS

Small Radius Omni-Grid conveyor belts can negotiate a much tighter turn than regular Omni-Grid belts. In general, the inside radius can be equal to 1.1 times the belt width, making Small Radius Omni-Grid ideal for use in applications where floor space is limited. Small Radius Omni-Grid can turn either left or right, pivoting about a center link.

Omni-Grid® 360 Weld Link

Competitor Link

DIRECTION

Proven Reliability

All Ashworth belts are rated for 100,000 cycles versus competition ratings of only 50,000 cycles

Added Strength & Easy to Clean

Patent pending zero-tension, 360° buttonless welds increase load bearing capacity and are easier to clean versus traditional bridge welds

Reduced Wear

Patented “protrusion leg” design enables the belt to run smoother with less system wear

Increased Belt Life

Patented coining feature reduces run-in wear and increases belt life

Does this meet your project needs?

Does this meet your project needs?

Does this meet your project needs?

Let’s get started!

Let’s get started!

Let’s get started!

Specifications

Technical Specifications

Select another product option

| Technical Specifications | Units | Small Radius Omni-Grid® 360 075 |

|---|---|---|

| Turn Ratio | 1.1-2.0 | |

| Pitch | in. [mm] | 0.75 [19.0] |

| Available Widths: Curve/Spiral | in. [mm] | 12-48 (304.8-1219) |

| Available Widths: Straight Run | in. [mm] | 12-48 (304.8-1219.2) |

| Link Height | in. [mm] | 0.44 [11.1] |

| Rod Diameter/Material | in. [mm] | 0.192 (4.9) Metal |

| Conveying Surface | in. [mm] | Width -1.50 [-38.10] |

| Allowable Tension (Curve/Spiral) | lb. [kg] | 150 [68] at 100,000 cycles |

| Allowable Tension (Straight Run) | lb. [kg] | 300 [136] at 100,000 cycles |

| Turn Direction | Uni-directional (left or right-must specify direction) | |

| Mode of Turning | Inside edge collapses in turn | |

| Method of Drive | Sprockets driven on links |

Available Sprocket Options

Sprocket Reference

Select another sprocket size

Select a product

| Nom. Size | Display | Teeth | Pitch Diameter in (mm) | Hub Diameter in (mm) | Bore Min in (mm) | Bore Max in (mm) |

|---|---|---|---|---|---|---|

| 3 | #3-12 Hardened Steel | 12 | 2.9 (73.66) | 2.36 (59.94) | 1 (25.4) | 1.8 (45.72) |

| 3 | #3-12 Hardened Steel | 12 | 2.9 (73.66) | 2.36 (59.94) | 1 (25.4) | 1.8 (45.72) |

| 3 | #3-12 T303 | 12 | 2.9 (73.66) | 2.36 (59.94) | 1 (25.4) | 1.8 (45.72) |

| 3 | #3-12 T303 | 12 | 2.9 (73.66) | 2.36 (59.94) | 0.94 (23.81) | 1.8 (45.72) |

| 3 | #3-12 UHMW | 12 | 2.9 (73.66) | 2.25 (57.15) | 0 | 1.5 (38.1) |

| 3 | #3-16 UHMW | 16 | 3.84 (97.63) | 3 (76.2) | 1.58 (40.01) | 2.13 (54.1) |

| 3 | #3-16 UHMW | 16 | 3.84 (97.64) | 3 (76.2) | 1 (25.4) | 2.13 (54.1) |

| 4 | #4-17 T303 | 17 | 4.08 (103.68) | 3.58 (90.81) | 0 | 2.83 (71.88) |

| 4 | #4-17 UHMW | 17 | 4.08 (103.68) | 3.58 (90.81) | 0.75 (19.05) | 2.58 (65.53) |

| 4 | #4-17 UHMW | 17 | 4.08 (103.68) | 3.58 (90.81) | 1 (25.4) | 2.58 (65.53) |

| 4 | #4-18 T303 | 18 | 4.32 (109.68) | 3.82 (96.9) | 0 | 2.95 (74.93) |

| 4 | #4-18 T303 | 18 | 4.32 (109.68) | 3.82 (96.9) | 1.58 (40.01) | 2.82 (71.63) |

| 5 | #5-19 UHMW | 19 | 4.56 (115.75) | 4.06 (103.05) | 0.75 (19.05) | 2.94 (74.68) |

| 5 | #5-21 T303 | 21 | 5.03 (127.81) | 4.54 (115.27) | 1 (25.4) | 3.55 (90.17) |

| 5 | #5-21 UHMW | 21 | 5.03 (127.81) | 4.54 (115.27) | 1 (25.4) | 3.42 (86.87) |

| 5 | #5-21 UHMW FS | 21 | 4.79 (121.67) | 4.54 (115.32) | 1 (25.4) | 3.42 (86.87) |

| 6 | #6 UHMW FI | 0 | 0 | 6 (152.4) | 0.75 (19.05) | 4.64 (117.86) |

| 6 | #6 UHMW I | 0 | 0 | 6 (152.4) | 0.75 (19.05) | 4.64 (117.86) |

| 6 | #6-25 T303 | 25 | 5.98 (151.99) | 5.5 (139.67) | 0 | 4.39 (111.51) |

| 6 | #6-25 T303 | 25 | 5.98 (151.99) | 5.5 (139.67) | 0.5 (12.7) | 4.39 (111.51) |

| 6 | #6-25 UHMW | 25 | 5.98 (151.99) | 5.5 (139.67) | 0.88 (22.22) | 4.14 (105.16) |

| 6 | #6-26 T303 | 26 | 6.22 (158.04) | 5.73 (145.64) | 0 | 4.62 (117.35) |

| 6 | #6-26 T303 | 26 | 6.22 (158.04) | 5.73 (145.64) | 1.58 (40.01) | 4.62 (117.35) |

| 6 | #6-26 T303 | 26 | 6.22 (158.04) | 5.73 (145.64) | 1.58 (40.01) | 4.62 (117.35) |

| 6 | #6-26 UHMW | 26 | 6.22 (158.04) | 5.73 (145.64) | 1 (25.4) | 4.37 (111) |

| 6 | #6-27 UHMW | 27 | 6.42 (163.12) | 5.97 (151.61) | 0.88 (22.22) | 4.61 (117.09) |

| 8 | #8-34 UHMW | 34 | 8.13 (206.45) | 7.66 (194.46) | 1 (25.4) | 5.93 (150.62) |

3/4" pitch Omni-Grid can use #60 roller chain sprockets modified as follows:

- Face off sprocket such that the overall tooth width is 5/16 (7/94)

- Chamfer corners of the newly machined teeth

* Steel stock sprocket. More available upon request

*Maximum bores provide adequate material thickness for standard keyway. Specify special sized to be used when necessary.

Material Reference

- Acetal - polyoxymethylene plastic

- Celcon - acetal copolymer

- CI - cast iron

- Hardened Steel

- Nylon

- T303 - stainless steel

- T316 - stainless steel

- UMHW - polyethylene plastic

Belt Calculator

No Results

Base Belt Weight

Belt Pitch

Turn Ratio

Belt Strength

Min Filler Roll Diameter

Conveying Surface

Inside Conveying Surface

Outside Conveying Surface

Mesh Opening Size

Open Area Surface

Open Area Thru

Need more detailed information?

Need more detailed information?

Need more detailed information?

Options

Product Options

Omni-Tough Mesh Overlay

- Stainless steel, spring wire, spiral overlay available in 16 and 17 wire gauges.

- 2-1/2 times stronger and more damage-resistant than conventional wire overlays.

- Provides a flatter surface than standard overlays.

- More resistant to product sticking in freezer application.

Designation

B/U X - Y - Z

- B/U = Balanced or Unilateral Weave

- X = Number of Loops/Foot of Width

- Y = Number of Spirals/Foot of Length

- Z = Wire Gauge of Overlay

Examples:

B30-16-16

U42-16-17

Need more detailed information?

Need more detailed information?

Need more detailed information?

Downloads

Downloads

Technical Bulletins

Installation, Assembly & Maintenance Instructions

Conveyor System Review Form

Illustrations

-

ROD ONLY OG360 WELD 075

-

B18-16-16 OG360 WELD 075

-

B30-16-16 OG360 WELD 075

-

B36-16-16 OG360 WELD 075

-

B42-16-16 OG360 WELD 075

-

B48-16-16 OG360 WELD 075

-

B54-16-16 OG360 WELD 075

-

B72-16-16 OG360 WELD 075

-

ROD ONLY OG360 WELD 100

-

B18-12-16 OG360 WELD 100

-

B24-12-16 OG360 WELD 100

-

B30-12-16 OG360 WELD 100

-

B36-12-16 OG360 WELD 100

-

B42-12-16 OG360 WELD 100

-

B48-12-16 OG360 WELD 100

-

B54-12-16 OG360 WELD 100

-

B60-12-16 OG360 WELD 100

-

B72-12-16 OG360 WELD 100

-

U48-12-17 OG360 WELD 100

-

U60-12-16 OG360 WELD 100

-

U72-12-16 OG360 WELD 100

-

ROD ONLY OG360 WELD 150

-

B18-8-16 OG360 WELD 150

-

B24-8-16 OG360 WELD 150

-

B24-8-17 OG360 WELD 150 IGE

-

B30-8-16 OG360 WELD 150

-

B36-8-16 OG360 WELD 150

-

B42-8-16 OG360 WELD 150

-

B54-8-16 OG360 WELD 150

-

B72-8-17 OG360 WELD 150

-

U48-8-16 OG360 WELD 150

-

U54-8-17 OG360 WELD 150

-

OG360 100 H96 12 17

-

OG360 100 Rod Only

-

OG360 100 U48 12 17

-

OG360 100 U54 12 16

-

OG360 100 U54 12 17

-

OG360 100 U60 12 16

-

OG360 100 U60 12 17

-

OG360 100 U72 12 16

-

OG360 100 U72 12 17

-

OG360 150 B18 8 16

-

OG360 150 B18 8 17

-

OG360 150 B24 8 16

-

OG360 150 B24 8 17

-

OG360 150 B30 8 16

-

OG360 150 B30 8 17

-

OG360 150 B36 8 16

-

OG360 150 B36 8 17

-

OG360 150 B42 8 16

-

OG360 150 B42 8 17

-

OG360 150 B54 8 16

-

OG360 150 B54 8 17

-

OG360 150 B72 8 17

-

OG360 150 Rod Only

-

OG360 150 U36 8 16

-

OG360 150 U48 8 16

-

OG360 150 U48 8 17

-

OG360 150 U54 8 16

-

OG360 150 U54 8 17

-

OG360 075 B18 16 16

-

OG360 075 B24 16 16

-

OG360 075 B24 16 17

-

OG360 075 B30 16 16

-

OG360 075 B30 16 17

-

OG360 075 B36 16 16

-

OG360 075 B36 16 17

-

OG360 075 B42 16 16

-

OG360 075 B42 16 17

-

OG360 075 B48 16 16

-

OG360 075 B48 16 17

-

OG360 075 B54 16 16

-

OG360 075 B54 16 17

-

OG360 075 B60 16 16

-

OG360 075 B60 16 17

-

OG360 075 B72 16 16

-

OG360 075 B72 16 17

-

OG360 075 H106 16 16

-

OG360 075 H106 16 17

-

OG360 075 H60 16 16

-

OG360 075 H60 16 17

-

OG360 075 H72 16 16

-

OG360 075 H72 16 17

-

OG360 075 H84 16 16

-

OG360 075 H84 16 17

-

OG360 075 H96 16 16

-

OG360 075 H96 16 17

-

OG360 075 NO MESH

-

OG360 075 Rod Only

-

OG360 075 U36 16 16

-

OG360 100 B30 12 17

-

OG360 100 B18 12 16

-

OG360 100 B18 12 17

-

OG360 100 B24 12 16

-

OG360 100 B24 12 17

-

OG360 100 B30 12 16

-

OG360 100 B36 12 16

-

OG360 100 B36 12 17

-

OG360 100 B42 12 16

-

OG360 100 B42 12 17

-

OG360 100 B48 12 16

-

OG360 100 B48 12 17

-

OG360 100 B54 12 16

-

OG360 100 B54 12 17

-

OG360 100 B60 12 16

-

OG360 100 B60 12 17

-

OG360 100 B72 12 16

-

OG360 100 B72 12 17

-

OG360 100 H106 12 16

-

OG360 100 H106 12 17

-

OG360 100 H60 12 16

-

OG360 100 H60 12 17

-

OG360 100 H72 12 16

-

OG360 100 H72 12 17

-

OG360 100 H84 12 16

-

OG360 100 H84 12 17

-

OG360 100 H96 12 16

Features

SMALL RADIUS OMNI-GRID® 360 100 WELD

BELTS THAT RUN SMOOTHER, STRONGER, LONGER

BELTS THAT RUN SMOOTHER, STRONGER, LONGER

SPIRAL

LOTENSION

HYGENIC

TIGHT, 1.1 TURN RATIO FOR SMALL FOOTPRINT OPERATIONS

Small Radius Omni-Grid conveyor belts can negotiate a much tighter turn than regular Omni-Grid belts. In general, the inside radius can be equal to 1.1 times the belt width, making Small Radius Omni-Grid ideal for use in applications where floor space is limited. Small Radius Omni-Grid can turn either left or right, pivoting about a center link.

Omni-Grid® 360 Weld Link

Competitor Link

DIRECTION

Proven Reliability

All Ashworth belts are rated for 100,000 cycles versus competition ratings of only 50,000 cycles

Added Strength & Easy to Clean

Patent pending zero-tension, 360° buttonless welds increase load bearing capacity and are easier to clean versus traditional bridge welds

Reduced Wear

Patented “protrusion leg” design enables the belt to run smoother with less system wear

Increased Belt Life

Patented coining feature reduces run-in wear and increases belt life

Does this meet your project needs?

Does this meet your project needs?

Does this meet your project needs?

Let’s get started!

Let’s get started!

Let’s get started!

Specifications

Technical Specifications

Select another product option

| Technical Specifications | Units | Small Radius Omni-Grid® 360 100 |

|---|---|---|

| Turn Ratio | 1-2.0 | |

| Pitch | in. [mm] | 1.08 [27.4] |

| Available Widths: Curve/Spiral | in. [mm] | 12-48 (304.8-1219) |

| Available Widths: Straight Run | in. [mm] | 12-48 (304.8-1219.2) |

| Link Height | in. [mm] | 0.50 [12.7] |

| Rod Diameter/Material | in. [mm] | 0.192 (4.9) Metal |

| Conveying Surface | in. [mm] | Width -1.77 [-44.96] |

| Allowable Tension (Curve/Spiral) | lb. [kg] | 150 [68] at 100,000 cycles |

| Allowable Tension (Straight Run) | lb. [kg] | 300 [136] at 100,000 cycles |

| Turn Direction | Uni-directional (left or right-must specify direction) | |

| Mode of Turning | Inside edge collapses in turn | |

| Method of Drive | Sprockets driven on links |

Available Sprocket Options

Sprocket Reference

Select another sprocket size

Select a product

| Nom. Size | Display | Teeth | Pitch Diameter in (mm) | Hub Diameter in (mm) | Bore Min in (mm) | Bore Max in (mm) |

|---|---|---|---|---|---|---|

| 3 | #3-9 Hardened Steel | 9 | 0 | 2.45 (62.23) | 1 (25.4) | 1.83 (46.48) |

| 3 | #3-9 T303 | 9 | 3.16 (80.26) | 2.46 (62.48) | 1 (25.4) | 1.84 (46.74) |

| 3 | #3-9 T303 | 9 | 3.16 (80.26) | 2.46 (62.48) | 1 (25.4) | 1.84 (46.74) |

| 3 | #3-9 T303 | 9 | 3.16 (80.26) | 2.46 (62.48) | 1.25 (31.75) | 1.84 (46.74) |

| 3 | #3-9 T303 | 9 | 3.16 (80.26) | 2.46 (62.48) | 0.94 (23.81) | 1.84 (46.74) |

| 3 | #3-9 T316 | 9 | 3.16 (80.26) | 2.46 (62.48) | 1.44 (36.51) | 1.84 (46.74) |

| 3 | #3-9 UHMW | 9 | 3.16 (80.26) | 2.53 (64.26) | 1 (25.4) | 1.72 (43.69) |

| 3 | #3-9 UHMW | 9 | 3.16 (80.26) | 2.53 (64.26) | 0 | 1.72 (43.69) |

| 4 | #4 UHMW FI | 0 | 0 | 3.92 (99.57) | 0.75 (19.05) | 2.93 (74.42) |

| 4 | #4 UHMW I | 0 | 0 | 3.92 (99.57) | 0 | 2.93 (74.42) |

| 4 | #4-11 T303 | 11 | 3.83 (97.36) | 3.18 (80.72) | 0 | 2.07 (52.58) |

| 4 | #4-11 T303 | 11 | 3.83 (97.36) | 3.18 (80.72) | 0 | 2.44 (61.98) |

| 4 | #4-12 T303 | 12 | 4.17 (105.97) | 3.54 (89.92) | 0 | 2.8 (71.12) |

| 4 | #4-12 T316 | 12 | 4.17 (105.97) | 3.54 (89.92) | 0 | 2.8 (71.12) |

| 4 | #4-12 UHMW | 12 | 4.17 (105.97) | 3.45 (87.63) | 0.75 (19.05) | 2.46 (62.48) |

| 4 | #4-13 Celcon | 13 | 4.4 (111.76) | 3.9 (99.06) | 1 (25.4) | 2.91 (73.91) |

| 4 | #4-13 CI | 13 | 4.53 (115.09) | 3.91 (99.22) | 0 | 3.04 (77.22) |

| 4 | #4-13 T316 | 13 | 4.53 (115.09) | 3.91 (99.22) | 0 | 3.04 (77.22) |

| 4 | #4-13 UHMW | 13 | 4.53 (115.06) | 3.9 (99.06) | 1 (25.4) | 2.91 (73.91) |

| 5 | #5-15 T303 | 15 | 5.2 (131.95) | 4.58 (116.36) | 0 | 3.59 (91.19) |

| 5 | #5-15 UHMW | 15 | 5.2 (131.95) | 4.58 (116.36) | 2 (50.8) | 3.46 (87.88) |

| 6 | #6 UHMW FI | 0 | 0 | 5.65 (143.51) | 0.75 (19.05) | 4.29 (108.97) |

| 6 | #6 UHMW I | 0 | 0 | 5.65 (143.51) | 0 | 4.29 (108.97) |

| 6 | #6-18 CI | 18 | 6.24 (158.5) | 5.66 (143.67) | 0 | 3.75 (95.25) |

| 6 | #6-18 Nylon | 18 | 6.24 (158.5) | 5.65 (143.51) | 1 (25.4) | 4.54 (115.32) |

| 6 | #6-18 T316 | 18 | 6.24 (158.5) | 5.66 (143.67) | 1 (25.4) | 3.75 (95.25) |

| 6 | #6-18 UHMW | 18 | 6.24 (158.5) | 5.65 (143.51) | 0 | 4.29 (108.97) |

| 6 | #6-18 UHMW FS | 18 | 6.15 (156.16) | 5.65 (143.46) | 0 | 4.29 (108.97) |

| 6 | #6-18 UHMW Product Release | 18 | 6.4 (162.51) | 5.65 (143.46) | 1 (25.4) | 4.29 (108.97) |

| 6 | #6-18 UHMW Split | 18 | 6.24 (158.5) | 5.65 (143.46) | 0 | 4.29 (108.97) |

| 6 | #6-19 T303 | 19 | 6.55 (166.47) | 6.03 (153.21) | 0 | 4.8 (121.92) |

| 6 | #6-19 UHMW | 19 | 6.55 (166.47) | 6.03 (153.21) | 1.18 (30) | 4.67 (118.62) |

| 8 | #8 UHMW FI | 0 | 0 | 7.38 (187.45) | 0.75 (19.05) | 5.89 (149.61) |

| 8 | #8 UHMW I | 0 | 0 | 7.38 (187.45) | 0 | 5.89 (149.61) |

| 8 | #8-23 CI | 23 | 7.41 (188.11) | 7.41 (188.11) | 0 | 5.9 (149.86) |

| 8 | #8-23 CI | 23 | 7.96 (202.18) | 7.41 (188.12) | 0 | 4.75 (120.65) |

| 8 | #8-23 T316 | 23 | 7.96 (202.18) | 7.41 (188.12) | 0 | 4.75 (120.65) |

| 8 | #8-23 T316 | 23 | 7.97 (202.41) | 7.41 (188.12) | 1 (25.4) | 4.75 (120.65) |

| 8 | #8-23 UHMW | 23 | 7.96 (202.18) | 7.39 (187.71) | 1 (25.4) | 5.9 (149.86) |

| 8 | #8-23 UHMW Split | 23 | 7.89 (200.33) | 7.39 (187.63) | 0 | 5.9 (149.86) |

| 10 | #10-31 CI | 31 | 10.72 (272.29) | 10.16 (258.06) | 0 | 8.67 (220.22) |

| 10 | #10-31 T316 | 31 | 10.72 (272.29) | 10.16 (258.06) | 0 | 8.67 (220.22) |

| 10 | #10-31 UHMW | 31 | 10.66 (270.76) | 10.16 (258.06) | 0.99 (25.02) | 8.42 (213.87) |

| 12 | #12-37 UHMW | 37 | 12.74 (323.49) | 12.24 (310.79) | 0.99 (25.02) | 10.49 (266.45) |

* Stock sprockets: UHMWPE, Steel. More available upon request

*Maximum bores provide adequate material thickness for standard keyway. Specify special sized to be used when necessary.

Material Reference

- Acetal - polyoxymethylene plastic

- Celcon - acetal copolymer

- CI - cast iron

- Hardened Steel

- Nylon

- T303 - stainless steel

- T316 - stainless steel

- UMHW - polyethylene plastic

Need more detailed information?

Need more detailed information?

Need more detailed information?

Belt Calculator

No Results

Base Belt Weight

Belt Pitch

Turn Ratio

Belt Strength

Min Filler Roll Diameter

Conveying Surface

Inside Conveying Surface

Outside Conveying Surface

Mesh Opening Size

Open Area Surface

Open Area Thru

Need more detailed information?

Need more detailed information?

Need more detailed information?

Options

Product Options

Omni-Tough Mesh Overlay

- Stainless steel, spring wire, spiral overlay available in 16 and 17 wire gauges.

- 2-1/2 times stronger and more damage-resistant than conventional wire overlays.

- Provides a flatter surface than standard overlays.

- More resistant to product sticking in freezer application.

Designation

B/U X - Y - Z

- B/U = Balanced or Unilateral Weave

- X = Number of Loops/Foot of Width

- Y = Number of Spirals/Foot of Length

- Z = Wire Gauge of Overlay

Examples:

B30-16-16

U42-16-17

Need more detailed information?

Need more detailed information?

Need more detailed information?

Downloads

Downloads

Technical Bulletins

Installation, Assembly & Maintenance Instructions

Conveyor System Review Form

Illustrations

-

ROD ONLY OG360 WELD 075

-

B18-16-16 OG360 WELD 075

-

B30-16-16 OG360 WELD 075

-

B36-16-16 OG360 WELD 075

-

B42-16-16 OG360 WELD 075

-

B48-16-16 OG360 WELD 075

-

B54-16-16 OG360 WELD 075

-

B72-16-16 OG360 WELD 075

-

ROD ONLY OG360 WELD 100

-

B18-12-16 OG360 WELD 100

-

B24-12-16 OG360 WELD 100

-

B30-12-16 OG360 WELD 100

-

B36-12-16 OG360 WELD 100

-

B42-12-16 OG360 WELD 100

-

B48-12-16 OG360 WELD 100

-

B54-12-16 OG360 WELD 100

-

B60-12-16 OG360 WELD 100

-

B72-12-16 OG360 WELD 100

-

U48-12-17 OG360 WELD 100

-

U60-12-16 OG360 WELD 100

-

U72-12-16 OG360 WELD 100

-

ROD ONLY OG360 WELD 150

-

B18-8-16 OG360 WELD 150

-

B24-8-16 OG360 WELD 150

-

B24-8-17 OG360 WELD 150 IGE

-

B30-8-16 OG360 WELD 150

-

B36-8-16 OG360 WELD 150

-

B42-8-16 OG360 WELD 150

-

B54-8-16 OG360 WELD 150

-

B72-8-17 OG360 WELD 150

-

U48-8-16 OG360 WELD 150

-

U54-8-17 OG360 WELD 150

-

OG360 100 H96 12 17

-

OG360 100 Rod Only

-

OG360 100 U48 12 17

-

OG360 100 U54 12 16

-

OG360 100 U54 12 17

-

OG360 100 U60 12 16

-

OG360 100 U60 12 17

-

OG360 100 U72 12 16

-

OG360 100 U72 12 17

-

OG360 150 B18 8 16

-

OG360 150 B18 8 17

-

OG360 150 B24 8 16

-

OG360 150 B24 8 17

-

OG360 150 B30 8 16

-

OG360 150 B30 8 17

-

OG360 150 B36 8 16

-

OG360 150 B36 8 17

-

OG360 150 B42 8 16

-

OG360 150 B42 8 17

-

OG360 150 B54 8 16

-

OG360 150 B54 8 17

-

OG360 150 B72 8 17

-

OG360 150 Rod Only

-

OG360 150 U36 8 16

-

OG360 150 U48 8 16

-

OG360 150 U48 8 17

-

OG360 150 U54 8 16

-

OG360 150 U54 8 17

-

OG360 075 B18 16 16

-

OG360 075 B24 16 16

-

OG360 075 B24 16 17

-

OG360 075 B30 16 16

-

OG360 075 B30 16 17

-

OG360 075 B36 16 16

-

OG360 075 B36 16 17

-

OG360 075 B42 16 16

-

OG360 075 B42 16 17

-

OG360 075 B48 16 16

-

OG360 075 B48 16 17

-

OG360 075 B54 16 16

-

OG360 075 B54 16 17

-

OG360 075 B60 16 16

-

OG360 075 B60 16 17

-

OG360 075 B72 16 16

-

OG360 075 B72 16 17

-

OG360 075 H106 16 16

-

OG360 075 H106 16 17

-

OG360 075 H60 16 16

-

OG360 075 H60 16 17

-

OG360 075 H72 16 16

-

OG360 075 H72 16 17

-

OG360 075 H84 16 16

-

OG360 075 H84 16 17

-

OG360 075 H96 16 16

-

OG360 075 H96 16 17

-

OG360 075 NO MESH

-

OG360 075 Rod Only

-

OG360 075 U36 16 16

-

OG360 100 B30 12 17

-

OG360 100 B18 12 16

-

OG360 100 B18 12 17

-

OG360 100 B24 12 16

-

OG360 100 B24 12 17

-

OG360 100 B30 12 16

-

OG360 100 B36 12 16

-

OG360 100 B36 12 17

-

OG360 100 B42 12 16

-

OG360 100 B42 12 17

-

OG360 100 B48 12 16

-

OG360 100 B48 12 17

-

OG360 100 B54 12 16

-

OG360 100 B54 12 17

-

OG360 100 B60 12 16

-

OG360 100 B60 12 17

-

OG360 100 B72 12 16

-

OG360 100 B72 12 17

-

OG360 100 H106 12 16

-

OG360 100 H106 12 17

-

OG360 100 H60 12 16

-

OG360 100 H60 12 17

-

OG360 100 H72 12 16

-

OG360 100 H72 12 17

-

OG360 100 H84 12 16

-

OG360 100 H84 12 17

-

OG360 100 H96 12 16

Features

OMNI-GRID® 360 75 WELD

OMNI-GRID® 360 75 WELD

HIGH DENSITY MESH

HIGH DENSITY MESH

BELTS THAT RUN SMOOTHER, STRONGER, LONGER

BELTS THAT RUN SMOOTHER, STRONGER, LONGER

SPIRAL

LOTENSION

HYGENIC

TIGHT, 1.1 TURN RATIO FOR SMALL FOOTPRINT OPERATIONS

Small Radius Omni-Grid conveyor belts can negotiate a much tighter turn than regular Omni-Grid belts. In general, the inside radius can be equal to 1.1 times the belt width, making Small Radius Omni-Grid ideal for use in applications where floor space is limited. Small Radius Omni-Grid can turn either left or right, pivoting about a center link.

Omni-Grid® 360 Weld Link

Competitor Link

DIRECTION

APPLICATIONS

Proven Reliability

All Ashworth belts are rated for 100,000 cycles versus competition ratings of only 50,000 cycles

Added Strength & Easy to Clean

Patent pending zero-tension, 360° buttonless welds increase load bearing capacity and are easier to clean versus traditional bridge welds

Reduced Wear

Patented “protrusion leg” design enables the belt to run smoother with less system wear

Increased Belt Life

Patented coining feature reduces run-in wear and increases belt life

Does this meet your project needs?

Does this meet your project needs?

Does this meet your project needs?

Let’s get started!

Let’s get started!

Let’s get started!

Specifications

Technical Specifications

Select another product option

| Technical Specifications | Units | OMNI-GRID® 360 75 - HIGH DENSITY MESH |

|---|---|---|

| Turn Ratio | 0-0.0 | |

| Pitch | in. [mm] | 0.75 [19.0] |

| Available Widths: Curve/Spiral | in. [mm] | 12-40 (304.8-1016) |

| Available Widths: Straight Run | in. [mm] | 12-60 (304.8-1524.0) |

| Link Height | in. [mm] | 0.44 [11.1] |

| Rod Diameter/Material | in. [mm] | 0.192 (4.9) Metal |

| Conveying Surface | in. [mm] | Width -2.23 [-56.64] |

| Allowable Tension (Curve/Spiral) | lb. [kg] | 200 [91] at 100,000 cycles |

| Allowable Tension (Straight Run) | lb. [kg] | 400 [181] at 100,000 cycles |

| Turn Direction | Bi-directional | |

| Mode of Turning | Inside edge collapses in turn | |

| Method of Drive | Sprockets driven on links |

Belt Calculator

No Results

Base Belt Weight

Belt Pitch

Turn Ratio

Belt Strength

Min Filler Roll Diameter

Conveying Surface

Inside Conveying Surface

Outside Conveying Surface

Mesh Opening Size

Open Area Surface

Open Area Thru

Need more detailed information?

Need more detailed information?

Need more detailed information?

Options

Product Options

Omni-Tough Mesh Overlay

- Stainless steel, spring wire, spiral overlay available in 16 and 17 wire gauges.

- 2-1/2 times stronger and more damage-resistant than conventional wire overlays.

- Provides a flatter surface than standard overlays.

- More resistant to product sticking in freezer application.

Designation

B/U X - Y - Z

- B/U = Balanced or Unilateral Weave

- X = Number of Loops/Foot of Width

- Y = Number of Spirals/Foot of Length

- Z = Wire Gauge of Overlay

Examples:

B30-16-16

U42-16-17

Downloads

Downloads

Technical Bulletins

Installation, Assembly & Maintenance Instructions

Conveyor System Review Form

Illustrations

-

ROD ONLY OG360 WELD 075

-

B18-16-16 OG360 WELD 075

-

B30-16-16 OG360 WELD 075

-

B36-16-16 OG360 WELD 075

-

B42-16-16 OG360 WELD 075

-

B48-16-16 OG360 WELD 075

-

B54-16-16 OG360 WELD 075

-

B72-16-16 OG360 WELD 075

-

ROD ONLY OG360 WELD 100

-

B18-12-16 OG360 WELD 100

-

B24-12-16 OG360 WELD 100

-

B30-12-16 OG360 WELD 100

-

B36-12-16 OG360 WELD 100

-

B42-12-16 OG360 WELD 100

-

B48-12-16 OG360 WELD 100

-

B54-12-16 OG360 WELD 100

-

B60-12-16 OG360 WELD 100

-

B72-12-16 OG360 WELD 100

-

U48-12-17 OG360 WELD 100

-

U60-12-16 OG360 WELD 100

-

U72-12-16 OG360 WELD 100

-

ROD ONLY OG360 WELD 150

-

B18-8-16 OG360 WELD 150

-

B24-8-16 OG360 WELD 150

-

B24-8-17 OG360 WELD 150 IGE

-

B30-8-16 OG360 WELD 150

-

B36-8-16 OG360 WELD 150

-

B42-8-16 OG360 WELD 150

-

B54-8-16 OG360 WELD 150

-

B72-8-17 OG360 WELD 150

-

U48-8-16 OG360 WELD 150

-

U54-8-17 OG360 WELD 150

-

OG360 100 H96 12 17

-

OG360 100 Rod Only

-

OG360 100 U48 12 17

-

OG360 100 U54 12 16

-

OG360 100 U54 12 17

-

OG360 100 U60 12 16

-

OG360 100 U60 12 17

-

OG360 100 U72 12 16

-

OG360 100 U72 12 17

-

OG360 150 B18 8 16

-

OG360 150 B18 8 17

-

OG360 150 B24 8 16

-

OG360 150 B24 8 17

-

OG360 150 B30 8 16

-

OG360 150 B30 8 17

-

OG360 150 B36 8 16

-

OG360 150 B36 8 17

-

OG360 150 B42 8 16

-

OG360 150 B42 8 17

-

OG360 150 B54 8 16

-

OG360 150 B54 8 17

-

OG360 150 B72 8 17

-

OG360 150 Rod Only

-

OG360 150 U36 8 16

-

OG360 150 U48 8 16

-

OG360 150 U48 8 17

-

OG360 150 U54 8 16

-

OG360 150 U54 8 17

-

OG360 075 B18 16 16

-

OG360 075 B24 16 16

-

OG360 075 B24 16 17

-

OG360 075 B30 16 16

-

OG360 075 B30 16 17

-

OG360 075 B36 16 16

-

OG360 075 B36 16 17

-

OG360 075 B42 16 16

-

OG360 075 B42 16 17

-

OG360 075 B48 16 16

-

OG360 075 B48 16 17

-

OG360 075 B54 16 16

-

OG360 075 B54 16 17

-

OG360 075 B60 16 16

-

OG360 075 B60 16 17

-

OG360 075 B72 16 16

-

OG360 075 B72 16 17

-

OG360 075 H106 16 16

-

OG360 075 H106 16 17

-

OG360 075 H60 16 16

-

OG360 075 H60 16 17

-

OG360 075 H72 16 16

-

OG360 075 H72 16 17

-

OG360 075 H84 16 16

-

OG360 075 H84 16 17

-

OG360 075 H96 16 16

-

OG360 075 H96 16 17

-

OG360 075 NO MESH

-

OG360 075 Rod Only

-

OG360 075 U36 16 16

-

OG360 100 B30 12 17

-

OG360 100 B18 12 16

-

OG360 100 B18 12 17

-

OG360 100 B24 12 16

-

OG360 100 B24 12 17

-

OG360 100 B30 12 16

-

OG360 100 B36 12 16

-

OG360 100 B36 12 17

-

OG360 100 B42 12 16

-

OG360 100 B42 12 17

-

OG360 100 B48 12 16

-

OG360 100 B48 12 17

-

OG360 100 B54 12 16

-

OG360 100 B54 12 17

-

OG360 100 B60 12 16

-

OG360 100 B60 12 17

-

OG360 100 B72 12 16

-

OG360 100 B72 12 17

-

OG360 100 H106 12 16

-

OG360 100 H106 12 17

-

OG360 100 H60 12 16

-

OG360 100 H60 12 17

-

OG360 100 H72 12 16

-

OG360 100 H72 12 17

-

OG360 100 H84 12 16

-

OG360 100 H84 12 17

-

OG360 100 H96 12 16