Ashworth's Woven Wire Belts are great for food processing or industrial applications.

WG Woven Wire Conveyor Belts

Ashworth Straight Running Friction Driven Belts are woven wire belts that are drum, as opposed to sprocket, driven. Within this product grouping are a host of woven wire belts, ranging from the simplest, conventional weave designs, to the most complex, tightly-woven compound balance weave belts. Some of our most popular belts are individually featured below. However, construction possibilities for straight running, friction driven belts are practically endless, considering the number of different materials and weave patterns are available. Contact an Ashworth associate for assistance in selecting a straight running friction driven belt that is specifically tailored for your application.

NOTE: Our woven belts are measured for length under tension.

WG Woven Wire Conveyor Belts

Specifications

Options

Downloads

Specifications

Technical Specifications

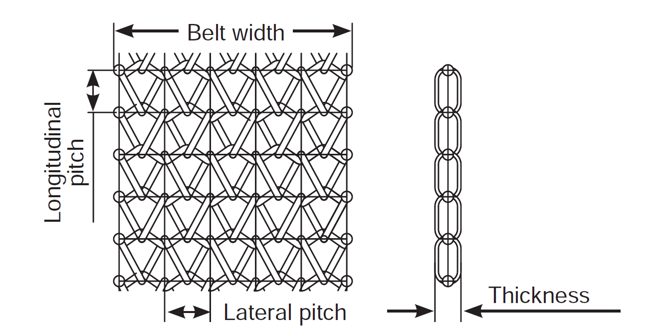

| Technical Specifications | Unit | |

|---|---|---|

| Material | Stainless, carbon, and galvanized steels, high temperature alloys | |

| Minimum Width | in. (mm) | 1.60 (40.6) |

| Maximum Width | in. (mm) | 216.00 (5486.4) |

| Weight | Dependent on mesh count and wire gauge | |

| Allowable Tension | Dependent on mesh count and wire gauge | |

| Conveying Surface | Full belt width | |

| Opening Size (Based on mesh count) | 40-70% depending on mesh count and wire size | |

| Method of Drive | Friction driven on flat-faced drums or terminal rolls | |

| Maximum Temperature | °F (°C) | Up to 2012 (1100) dependent upon material |

Belt Calculator

Base Belt Weight

Working Strength

Opening Size

Open Area Surface

Open Area Thru

Estimated Thickness

Min Drum Diameter

Need more detailed information?

Need more detailed information?

Need more detailed information?

Options

Product Options

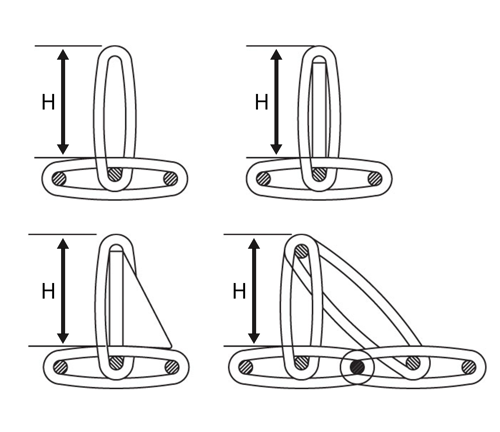

Balanced Weave

WG Balanced Weave belts are composed of right- and left-hand spirals joined by a connector rod. Edges are welded. The mesh choice for WG belts is nearly unlimited and is dependent upon requirements of the application, including product weight and support requirements, as well as process temperature.

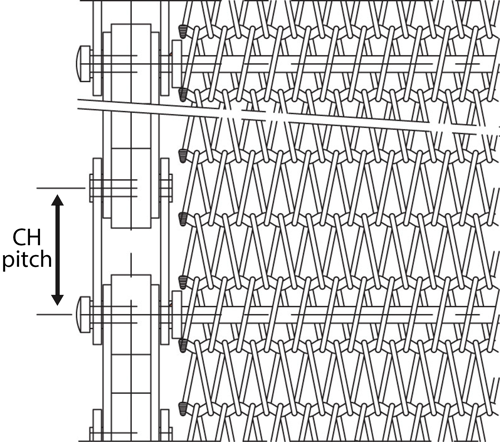

Special Features

WG belts can be manufactured with flights (Figure A) or as positive drive edge belts (figure B). Standard chains are hollow pin, in 0.5"(12.7mm), 0.63"(15.9mm), or 1"(25.4mm) pitch.

Figure A.

Figure B.

Downloads

Downloads

Technical Bulletins

Conveyor System Review Form