Cleatrac® Belt and Sprocket System

Select another product option

Features

Specifications

Options

Downloads

Features

CLEATRAC BELT & SPROCKET SYSTEM

CLEATRAC BELT & SPROCKET SYSTEM

CLEATRAC BELT & SPROCKET SYSTEM

EFFICIENT COST-EFFECTIVE

EFFICIENT COST-EFFECTIVE

POSITIVE DRIVE

STRAIGHT RUN

HYGENIC

THE INDUSTRY'S

TIGHTEST TRANSFER

THE INDUSTRY'S TIGHTEST TRANSFER

Ashworth’s Cleatrac® belt and sprocket system is the perfect food processing solution to accurately transfer even small products, minimize product damage, and keep your manufacturing process up and running. As the industry’s only supplier of customized conical-toothed sprockets that are perfectly matched with Cleatrac belt, Cleatrac belt and sprocket systems have a proven track record in delivering the perfect pairing.

An efficient, cost-effective solution, Cleatrac Belt & Sprockets Systems are guaranteed by Ashworth to deliver positive sprocket engagement to ensure precise product conveyance throughout the processing cycle. Cleatrac belts and sprockets are also compatible with the smallest nose bar diameters in the industry, all the way down to one-fifth of an inch (5.1 millimeters)

Ashworth’s Cleatrac® belt and sprocket system is the perfect food processing solution to accurately transfer even small products, minimize product damage, and keep your manufacturing process up and running. As the industry’s only supplier of customized conical-toothed sprockets that are perfectly matched with Cleatrac belt, Cleatrac belt and sprocket systems have a proven track record in delivering the perfect pairing.

An efficient, cost-effective solution, Cleatrac Belt & Sprockets Systems are guaranteed by Ashworth to deliver positive sprocket engagement to ensure precise product conveyance throughout the processing cycle. Cleatrac belts and sprockets are also compatible with the smallest nose bar diameters in the industry, all the way down to one-fifth of an inch (5.1 millimeters)

Eliminate Belt Wavering

Guaranteed true tracking with a positive drive sprocket system

Eliminate Belt Wavering

Guaranteed true tracking with a positive drive sprocket system

CLEATRAC BELT & SPROCKET SYSTEM

AT A GLANCE

CLEATRAC BELT & SPROCKET SYSTEM

AT A GLANCE

Minimize Product Damage:

- Guaranteed positive sprocket engagement ensures precise product conveyance

- The tightest product transfer solution in the industry

- Compatible with the industry’s smallest nose bar diameters

- Sprockets designed with conical shaped teeth have no sharp points that can damage spiral wires

- Available in various mesh configurations for precise product support and airflow for a wide range of applications

Reduce Operating Costs:

- Less expensive than chain-edge construction systems

- Engineered to deliver longer belt life than pin roll drives

- More durable and less prone to fatigue than single-plane wire designs

- Constructed with an easy-to-clean open balanced weave design

On Demand Availability:

- Standard widths are in stock and available for delivery within 24 hours

- Available complete with sprockets, support bearings, and filler rolls

DIRECTION

STRAIGHT RUN

APPLICATIONS

Durable & Energy Efficient

Withstands the toughest environments with half the mass of standard flat wire

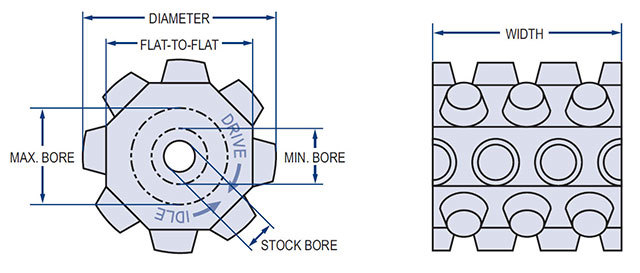

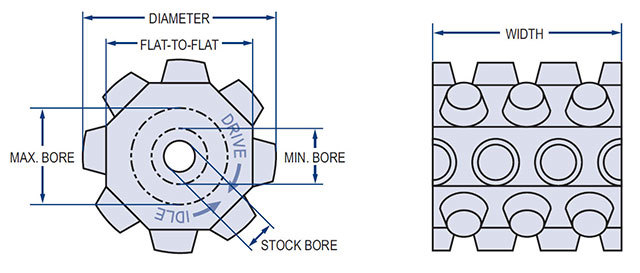

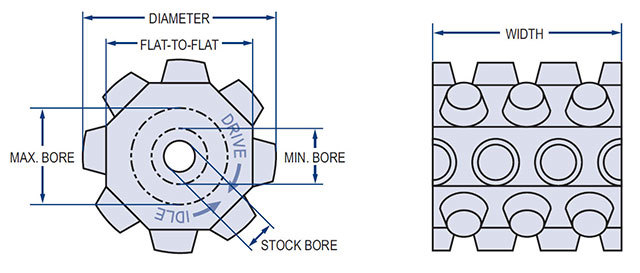

THE SPROCKET IS EQUALLY AS IMPORTANT AS THE BELT!

THE SPROCKET IS EQUALLY AS IMPORTANT AS THE BELT!

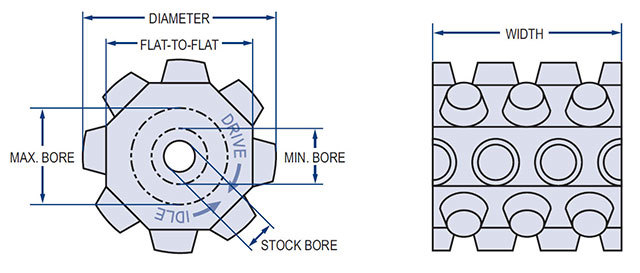

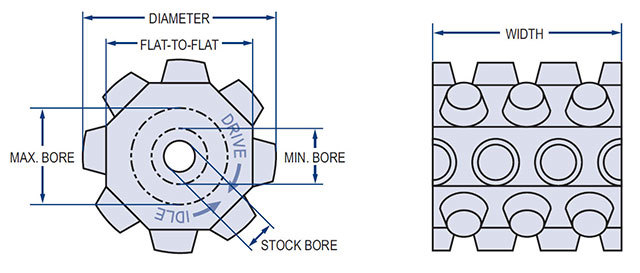

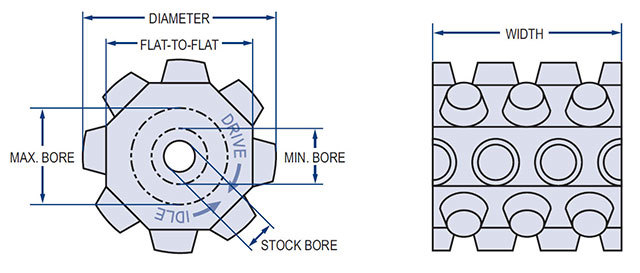

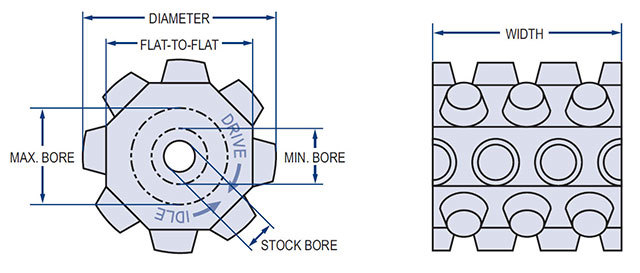

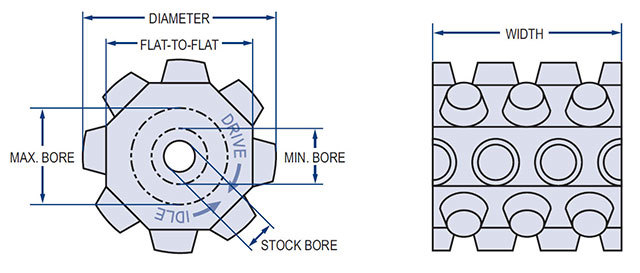

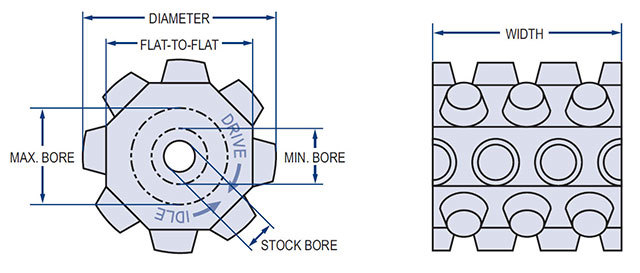

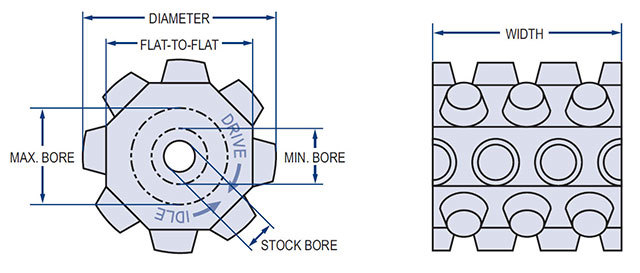

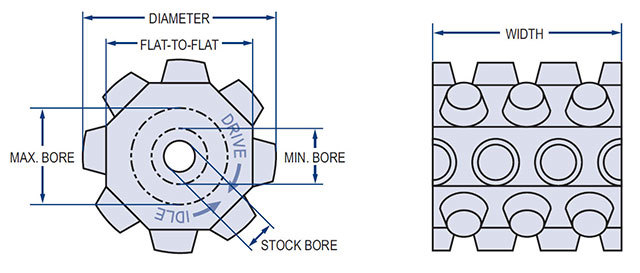

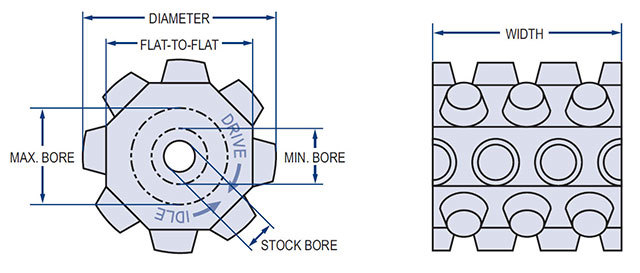

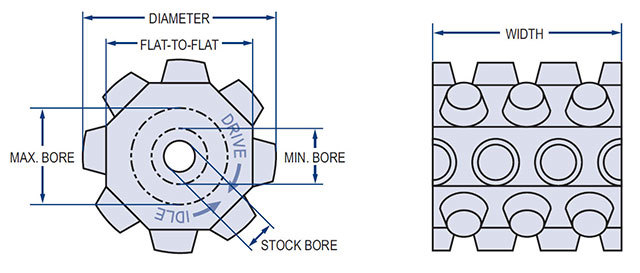

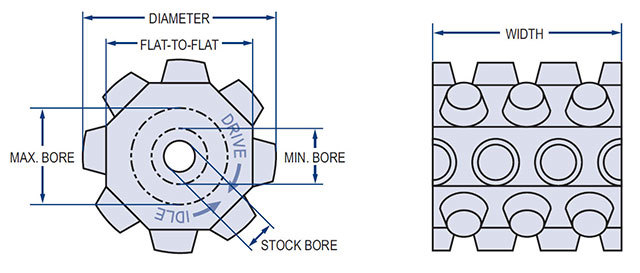

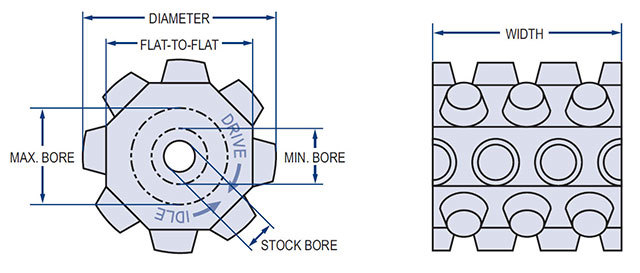

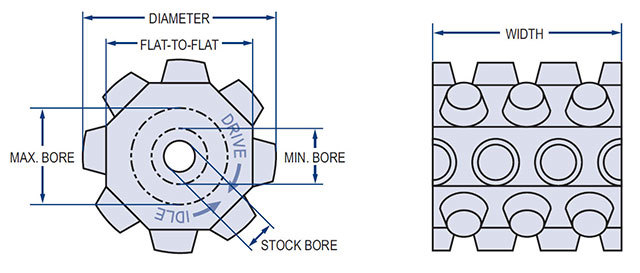

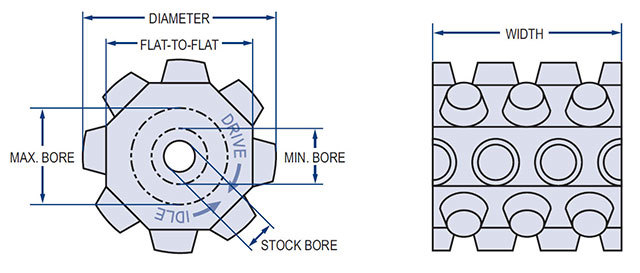

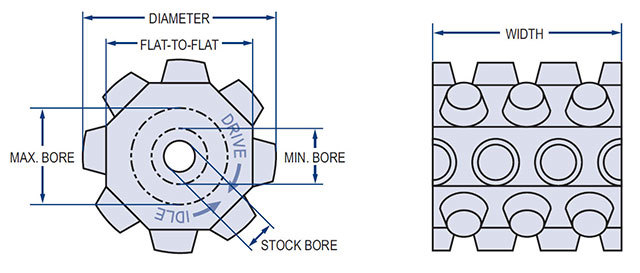

Manufactured in either UHMW polyethylene or T303 stainless steel, Cleatrac uses the perfect sprockets to positively drive mesh belting. Sprockets are available in a variety of sizes but special size sprockets may be manufactured to meet a customer’s needs.

Manufactured in either UHMW polyethylene or T303 stainless steel, Cleatrac uses the perfect sprockets to positively drive mesh belting. Sprockets are available in a variety of sizes but special size sprockets may be manufactured to meet a customer’s needs.

Positive drive provides true belt travel and minimum terminal diameters allow close transfer of product onto and off belt. Sprockets are bored oversize to allow lateral movement on the shaft compensating for changes in belt width due to temperature.

Positive drive provides true belt travel and minimum terminal diameters allow close transfer of product onto and off belt. Sprockets are bored oversize to allow lateral movement on the shaft compensating for changes in belt width due to temperature.

Improved Can Stability

Smooth even surface for tight can transfers

Does this meet your project needs?

Does this meet your project needs?

Does this meet your project needs?

Let’s get started!

Let’s get started!

Let’s get started!

Specifications

Belt Calculator

Belt Weight

Working Strength

Opening Size

Open Area Surface

Open Area Thru

Min Nose Diameter

Thickness

Available Sprocket Options

Sprocket Reference

Select another sprocket size

Select a product

| Nom. Size | Display | Teeth | Pitch Diameter in (mm) | Hub Diameter in (mm) | Bore Min in (mm) | Bore Max in (mm) |

|---|---|---|---|---|---|---|

| 1 | CTS 18-08 T303 | 8 | 1.75 (44.42) | 1.51 (38.38) | 0 | 1.08 (27.43) |

| 1 | CTS 18-08 UHMW | 8 | 1.75 (44.42) | 1.51 (38.38) | 0.25 (6.35) | 1 (25.4) |

| 1 | CTS 18-08 UHMW | 8 | 1.75 (44.42) | 1.51 (38.38) | 0.5 (12.7) | 1 (25.4) |

| 1 | CTS 18-08 UHMW | 8 | 1.75 (44.42) | 1.51 (38.38) | 0.75 (19.05) | 1 (25.4) |

| 1 | CTS 18-08 UHMW | 8 | 1.75 (44.42) | 1.51 (38.38) | 1 (25.4) | 1 (25.4) |

| 1 | CTS 30-08 T303 | 8 | 1.15 (29.29) | 0.94 (23.8) | 0 | 0.62 (15.88) |

| 1 | CTS 30-08 UHMW | 8 | 1.15 (29.29) | 0.94 (23.8) | 0.25 (6.35) | 0.62 (15.88) |

| 1 | CTS 30-08 UHMW | 8 | 1.15 (29.29) | 0.94 (23.8) | 0.5 (12.7) | 0.62 (15.88) |

| 1 | CTS 30-08 UHMW | 8 | 1.15 (29.29) | 0.94 (23.8) | 0.5 (12.7) | 0.62 (15.88) |

| 1 | CTS 30-08 UHMW | 8 | 1.15 (29.29) | 0.94 (23.8) | 0.62 (15.88) | 0.62 (15.88) |

| 1 | CTS 42-12 T303 SS | 12 | 1.19 (30.23) | 1 (25.5) | 0.5 (12.7) | 0.63 (16) |

| 1 | CTS 42-12 UHMW | 12 | 1.2 (30.38) | 1.01 (25.73) | 0.5 (12.7) | 0.5 (12.7) |

| 1 | CTS 42-12 UHMW | 12 | 1.2 (30.38) | 1.01 (25.73) | 0.5 (12.7) | 0.5 (12.7) |

| 1 | CTS 48-20 T303 SS | 20 | 1.52 (38.73) | 1.34 (34.01) | 0 | 0.96 (24.38) |

| 1 | CTS 48-20 UHMW | 20 | 1.52 (38.73) | 1.34 (34.01) | 0.5 (12.7) | 0.72 (18.29) |

| 1 | CTS 60-08 UHMW | 8 | 0.56 (14.2) | 0.43 (11.02) | 0.24 (5.99) | 0.25 (6.35) |

| 1 | CTS 60-08 UHMW | 8 | 0.56 (14.2) | 0.43 (11.02) | 0.2 (5.08) | 0.25 (6.35) |

| 1 | CTS 60-08 UHMW | 8 | 0.56 (14.2) | 0.43 (11.02) | 0.25 (6.35) | 0.25 (6.35) |

| 1 | CTS 60-28 T303 SS | 28 | 1.73 (43.89) | 1.57 (39.95) | 0.69 (17.53) | 1.14 (28.96) |

| 1 | CTS 60-28 UHMW | 28 | 1.73 (43.89) | 1.57 (39.95) | 0.75 (19.05) | 0.95 (24.13) |

| 1 | CTS60-28 T303 | 28 | 1.73 (43.89) | 1.57 (39.95) | 0 | 1.14 (28.96) |

| 2 | CTS 18-12 Acetal | 12 | 2.74 (69.55) | 2.5 (63.5) | 0.75 (19.05) | 1.88 (47.75) |

| 2 | CTS 18-12 T303 | 12 | 2.74 (69.55) | 2.5 (63.5) | 0.69 (17.53) | 1.88 (47.75) |

| 2 | CTS 18-12 UHMW | 12 | 2.74 (69.55) | 2.5 (63.5) | 1 (25.4) | 1.69 (42.93) |

| 2 | CTS 18-12 UHMW Blue | 12 | 2.74 (69.55) | 2.5 (63.5) | 0.75 (19.05) | 1.69 (42.93) |

| 2 | CTS 30-12 Acetal | 12 | 1.81 (46.02) | 1.6 (40.54) | 1 (25.4) | 1 (25.4) |

| 2 | CTS 30-12 T303 | 12 | 1.81 (46.02) | 1.6 (40.54) | 0.69 (17.53) | 1.16 (29.46) |

| 2 | CTS 30-12 UHMW | 12 | 1.81 (46.02) | 1.6 (40.54) | 0.25 (6.35) | 1 (25.4) |

| 2 | CTS 30-12 UHMW | 12 | 1.81 (46.02) | 1.6 (40.54) | 0.5 (12.7) | 1 (25.4) |

| 2 | CTS 30-12 UHMW | 12 | 1.81 (46.02) | 1.6 (40.54) | 0.75 (19.05) | 1 (25.4) |

| 2 | CTS 30-12 UHMW | 12 | 1.81 (46.02) | 1.6 (40.54) | 0.75 (19.05) | 1 (25.4) |

| 2 | CTS 30-12 UHMW | 12 | 1.81 (46.02) | 1.6 (40.54) | 1 (25.4) | 1 (25.4) |

| 2 | CTS 30-12 UHMW | 12 | 1.81 (46.02) | 1.6 (40.54) | 1 (25.4) | 1 (25.4) |

| 2 | CTS 42-20 T303 SS | 20 | 2.07 (52.48) | 1.88 (47.75) | 1 (25.4) | 1.38 (35.05) |

| 2 | CTS 42-20 T303 SS | 20 | 2.07 (52.48) | 1.88 (47.75) | 0 | 1.38 (35.05) |

| 2 | CTS 42-20 UHMW | 20 | 2.05 (52.07) | 1.88 (47.75) | 0.75 (19.05) | 1.19 (30.23) |

| 2 | CTS 42-20 UHMW | 20 | 2.05 (52.07) | 1.88 (47.75) | 1 (25.4) | 1.19 (30.23) |

| 2 | CTS 42-20 UHMW | 20 | 2.05 (52.07) | 1.88 (47.75) | 1 (25.4) | 1.19 (30.23) |

| 2 | CTS 48-24 T303 SS | 24 | 1.85 (46.86) | 1.66 (42.14) | 0 | 1.22 (30.99) |

| 2 | CTS 48-24 UHMW | 24 | 1.85 (46.86) | 1.66 (42.14) | 0.75 (19.05) | 0.97 (24.64) |

| 2 | CTS 60-12 T303 SS | 12 | 0.9 (22.81) | 0.77 (19.63) | 0.5 (12.7) | 0.5 (12.7) |

| 2 | CTS 60-12 T303 SS | 12 | 0.9 (22.81) | 0.77 (19.63) | 0 | 0.43 (10.92) |

| 2 | CTS 60-12 UHMW | 12 | 0.9 (22.81) | 0.77 (19.63) | 0.25 (6.35) | 0.5 (12.7) |

| 2 | CTS 60-12 UHMW | 12 | 0.9 (22.81) | 0.77 (19.63) | 0.5 (12.7) | 0.5 (12.7) |

| 2 | CTS 60-40 T303 SS | 40 | 2.49 (63.3) | 2.34 (59.41) | 0.69 (17.53) | 1.78 (45.21) |

| 2 | CTS 60-40 UHMW | 40 | 2.49 (63.3) | 2.34 (59.41) | 0.75 (19.05) | 1.53 (38.86) |

| 2 | CTS 60-40 UHMW | 40 | 2.49 (63.3) | 2.34 (59.41) | 0.75 (19.05) | 1.53 (38.86) |

| 2 | CTS 60-40 UHMW | 40 | 2.49 (63.3) | 2.34 (59.41) | 1 (25.4) | 1.53 (38.86) |

| 2 | CTS 60-40 UHMW Blue | 40 | 2.49 (63.3) | 2.34 (59.41) | 1 (25.4) | 1.53 (38.86) |

| 3 | CTS 18-14 Acetal | 14 | 3.21 (81.46) | 2.95 (74.98) | 1.5 (38.1) | 2.33 (59.18) |

| 3 | CTS 18-14 T303 | 14 | 3.2 (81.2) | 2.99 (75.84) | 0 | 0 |

| 3 | CTS 18-14 UHMW | 14 | 3.21 (81.46) | 2.95 (74.98) | 0.5 (12.7) | 2.08 (52.83) |

| 3 | CTS 30-14 T303 | 14 | 2.13 (54.09) | 1.91 (48.56) | 0 | 1.42 (36.07) |

| 3 | CTS 30-14 UHMW | 14 | 2.13 (54.04) | 1.93 (48.97) | 0.5 (12.7) | 1.24 (31.5) |

| 3 | CTS 42-24 T303 SS | 24 | 2.48 (63.07) | 2.3 (58.42) | 0.69 (17.53) | 1.74 (44.2) |

| 3 | CTS 42-24 UHMW | 24 | 2.48 (63.07) | 2.3 (58.42) | 0.75 (19.05) | 1.49 (37.85) |

| 3 | CTS 42-24 UHMW | 24 | 2.48 (63.07) | 2.3 (58.42) | 1 (25.4) | 1.49 (37.85) |

| 3 | CTS 48-32 T303 SS | 32 | 2.48 (63.06) | 2.31 (58.67) | 0.69 (17.46) | 1.75 (44.45) |

| 3 | CTS 48-32 UHMW | 32 | 2.48 (63.06) | 2.31 (58.67) | 0.75 (19.05) | 1.5 (38.1) |

| 3 | CTS 48-32 UHMW | 32 | 2.48 (63.06) | 2.31 (58.67) | 1 (25.4) | 1.5 (38.1) |

| 3 | CTS 60-14 UHMW | 14 | 1.05 (26.64) | 0.89 (22.63) | 0.5 (12.7) | 0.5 (12.7) |

| 3 | CTS 60-92 T303 SS | 92 | 5.81 (147.52) | 5.64 (143.15) | 0.69 (17.53) | 4.52 (114.81) |

| 3 | CTS 60-92 UHMW | 92 | 5.81 (147.52) | 5.64 (143.15) | 0.75 (19.05) | 4.28 (108.71) |

| 3 | CTS 60-92 UHMW | 92 | 5.81 (147.52) | 5.64 (143.15) | 1 (25.4) | 4.28 (108.71) |

| 3 | CTS 60-92 UHMW | 92 | 5.81 (147.52) | 5.64 (143.15) | 1 (25.4) | 4.28 (108.71) |

| 3 | CTS 60-92 UHMW | 92 | 5.64 (143.15) | 5.81 (147.52) | 1.25 (31.75) | 4.45 (113.03) |

| 3 | CTS 60-92 UHMW Blue | 92 | 5.81 (147.52) | 5.64 (143.15) | 0.75 (19.05) | 4.28 (108.71) |

| 3 | CTS 60-92 UHMW Blue | 92 | 5.81 (147.52) | 5.64 (143.15) | 1 (25.4) | 4.28 (108.71) |

| 4 | CTS 18-18 T303 | 18 | 3.95 (100.37) | 3.95 (100.3) | 0 | 3.08 (78.23) |

| 4 | CTS 18-18 UHMW | 18 | 4.19 (106.48) | 3.95 (100.43) | 1.18 (29.97) | 2.96 (75.18) |

| 4 | CTS 18-18 UHMW | 18 | 4.19 (106.48) | 3.95 (100.43) | 0.5 (12.7) | 2.96 (75.18) |

| 4 | CTS 18-18 UHMW | 18 | 4.19 (106.48) | 3.95 (100.43) | 0.75 (19.05) | 2.96 (75.18) |

| 4 | CTS 18-18 UHMW | 18 | 4.19 (106.48) | 3.95 (100.43) | 1 (25.4) | 2.96 (75.18) |

| 4 | CTS 30-16 T303 | 16 | 2.45 (62.28) | 2.23 (56.74) | 0 | 1.68 (42.67) |

| 4 | CTS 30-16 UHMW | 16 | 2.44 (62.05) | 2.23 (56.57) | 0.75 (19.05) | 1.48 (37.59) |

| 4 | CTS 42-30 T303 SS | 30 | 3.11 (79.11) | 2.93 (74.5) | 0 | 2.31 (58.67) |

| 4 | CTS 42-30 UHMW | 30 | 3.12 (79.12) | 2.93 (74.4) | 1 (25.4) | 2.06 (52.32) |

| 4 | CTS 48-48 T303 SS | 48 | 3.88 (98.63) | 3.7 (93.9) | 1.94 (49.21) | 2.95 (74.93) |

| 4 | CTS 60-24 Acetal | 24 | 1.86 (47.35) | 1.74 (44.17) | 0.92 (23.37) | 1.3 (33.02) |

| 4 | CTS 60-24 ACETAL | 24 | 1.86 (47.35) | 1.74 (44.17) | 0.66 (16.76) | 1.3 (33.02) |

| 4 | CTS 60-24 T303 SS | 24 | 1.86 (47.35) | 1.74 (44.17) | 0.69 (17.53) | 1.3 (33.02) |

| 4 | CTS 60-24 T316 SS | 24 | 1.86 (47.35) | 1.74 (44.17) | 1 (25.4) | 1.3 (33.02) |

| 4 | CTS 60-24 UHMW | 24 | 1.86 (47.35) | 1.74 (44.17) | 0.75 (19.05) | 1.05 (26.67) |

| 4 | CTS 60-24 UHMW | 24 | 1.86 (47.35) | 1.74 (44.17) | 0.75 (19.05) | 1.05 (26.67) |

| 4 | CTS 60-24 UHMW | 24 | 1.86 (47.35) | 1.74 (44.17) | 1 (25.4) | 1.05 (26.67) |

| 5 | CTS 18-20 Acetal | 20 | 4.67 (118.72) | 4.43 (112.65) | 1.58 (40.01) | 3.45 (87.63) |

| 5 | CTS 18-20 UHMW | 20 | 4.67 (118.72) | 4.43 (112.65) | 0.75 (19.05) | 3.32 (84.33) |

| 5 | CTS 30-18 T303 SS | 18 | 2.77 (70.46) | 2.56 (64.92) | 0 | 1.94 (49.28) |

| 5 | CTS 30-18 UHMW | 18 | 2.79 (70.92) | 2.58 (65.43) | 0.75 (19.05) | 1.77 (44.96) |

| 5 | CTS 30-18 UHMW | 18 | 2.79 (70.92) | 2.58 (65.43) | 1 (25.4) | 1.77 (44.96) |

| 5 | CTS 30-18 UHMW | 18 | 2.79 (70.92) | 2.58 (65.43) | 1 (25.4) | 1.77 (44.96) |

| 5 | CTS 42-32 T303 SS | 32 | 3.3 (83.76) | 3.12 (79.3) | 1.97 (50.01) | 2.38 (60.45) |

| 5 | CTS 42-32 T303 SS | 32 | 3.3 (83.76) | 3.12 (79.3) | 1 (25.4) | 2.38 (60.45) |

| 5 | CTS 42-32 T303 SS | 32 | 3.3 (83.76) | 3.12 (79.3) | 1.25 (31.75) | 2.38 (60.45) |

| 5 | CTS 42-32 T303 SS | 32 | 3.3 (83.76) | 3.12 (79.3) | 0.69 (17.46) | 2.38 (60.45) |

| 5 | CTS 42-32 UHMW | 32 | 3.33 (84.61) | 3.14 (79.88) | 0.75 (19.05) | 2.27 (57.66) |

| 5 | CTS 42-32 UHMW | 32 | 3.33 (84.61) | 3.14 (79.88) | 1 (25.4) | 2.27 (57.66) |

| 5 | CTS 48-74 T303 SS | 74 | 6.02 (152.93) | 5.84 (148.21) | 1 (25.4) | 4.72 (119.89) |

| 5 | CTS 60-42 T303 SS | 42 | 3.29 (83.57) | 3.16 (80.31) | 0.69 (17.53) | 2.42 (61.47) |

| 5 | CTS 60-42 T303 SS | 42 | 3.29 (83.57) | 3.16 (80.31) | 0 | 2.42 (61.47) |

| 5 | CTS 60-42 UHMW | 42 | 3.29 (83.57) | 3.16 (80.31) | 1 (25.4) | 2.29 (58.17) |

| 5 | CTS 60-42 UHMW | 42 | 3.29 (83.57) | 3.16 (80.31) | 0.75 (19.05) | 2.29 (58.17) |

| 5 | CTS 60-42 UHMW | 42 | 3.29 (83.57) | 3.16 (80.31) | 1 (25.4) | 2.29 (58.17) |

| 6 | CTS 30-20 T303 | 20 | 3.11 (78.99) | 2.89 (73.33) | 0.69 (17.53) | 2.27 (57.66) |

| 6 | CTS 30-20 UHMW | 20 | 3.11 (78.99) | 2.89 (73.33) | 0.75 (19.05) | 2.02 (51.31) |

| 6 | CTS 30-20 UHMW | 20 | 3.11 (78.99) | 2.89 (73.33) | 1 (25.4) | 2.02 (51.31) |

| 6 | CTS 30-20 UHMW | 20 | 3.11 (78.99) | 2.89 (73.33) | 1 (25.4) | 2.02 (51.31) |

| 6 | CTS 30-20 UHMW | 20 | 3.11 (78.99) | 2.89 (73.33) | 1.75 (44.45) | 2.02 (51.31) |

| 6 | CTS 42-40 T303 SS | 40 | 4.18 (106.22) | 4 (101.5) | 0 | 3.13 (79.5) |

| 6 | CTS 42-40 T303 SS | 40 | 4.18 (106.22) | 4 (101.5) | 1 (25.4) | 3.13 (79.5) |

| 6 | CTS 42-40 T303 SS | 40 | 4.18 (106.22) | 4 (101.5) | 0 | 3.13 (79.5) |

| 6 | CTS 42-40 UHMW | 40 | 4.18 (106.27) | 4 (101.5) | 0.5 (12.7) | 3 (76.2) |

| 6 | CTS 42-40 UHMW | 40 | 4.18 (106.27) | 4 (101.5) | 1 (25.4) | 3 (76.2) |

| 6 | CTS 42-40 UHMW | 40 | 4.18 (106.27) | 4 (101.5) | 1.25 (31.75) | 3 (76.2) |

| 6 | CTS 60-54 T303 SS | 54 | 4.24 (107.82) | 4.09 (103.96) | 0.69 (17.53) | 3.23 (82.04) |

| 6 | CTS 60-54 UHMW | 54 | 4.24 (107.82) | 4.09 (103.96) | 1 (25.4) | 2.98 (75.69) |

| 7 | CTS 30-22 UHMW | 22 | 3.42 (86.77) | 3.2 (81.23) | 1.5 (38.1) | 2.33 (59.18) |

| 7 | CTS 42-56 T303 SS | 56 | 5.88 (149.28) | 5.7 (144.68) | 0 | 4.58 (116.33) |

| 7 | CTS 42-56 UHMW | 56 | 5.88 (149.28) | 5.7 (144.68) | 1 (25.4) | 4.34 (110.24) |

| 7 | CTS 60-82 T303 SS | 82 | 6.45 (163.78) | 6.32 (160.6) | 0.75 (19.05) | 5.09 (129.29) |

| 7 | CTS 60-82 UHMW | 82 | 6.47 (164.46) | 6.32 (160.6) | 0.75 (19.05) | 4.84 (122.94) |

| 7 | CTS 60-82 UHMW | 82 | 6.47 (164.46) | 6.32 (160.6) | 1 (25.4) | 4.84 (122.94) |

| 7 | CTS 60-82 UHMW Blue | 82 | 6.47 (164.46) | 6.32 (160.6) | 0.75 (19.05) | 4.84 (122.94) |

| 8 | CTS 30-24 T303 | 24 | 3.74 (95.1) | 3.54 (89.81) | 0 | 2.79 (70.87) |

| 8 | CTS 30-24 T316L | 24 | 3.74 (95.1) | 3.54 (89.81) | 0 | 2.79 (70.87) |

| 8 | CTS 30-24 UHMW | 24 | 3.74 (95.12) | 3.52 (89.51) | 1 (25.4) | 2.53 (64.26) |

| 9 | CTS 30-26 T303 | 26 | 4.07 (103.25) | 3.84 (97.64) | 0.69 (17.53) | 2.98 (75.69) |

| 9 | CTS 30-26 UHMW | 26 | 4.07 (103.25) | 3.84 (97.64) | 0.75 (19.05) | 2.85 (72.39) |

| 10 | CTS 30-30 UHMW | 30 | 4.7 (119.28) | 4.49 (114.17) | 2.76 (70) | 3.38 (85.85) |

| 10 | CTS 30-30 UHMW | 30 | 4.7 (119.28) | 4.49 (114.17) | 0.75 (19.05) | 3.38 (85.85) |

| 11 | CTS 30-40 T303 | 40 | 6.29 (159.84) | 6.09 (154.71) | 0 | 4.86 (123.44) |

Material Reference

- Acetal - polyoxymethylene plastic

- Celcon - acetal copolymer

- CI - cast iron

- Hardened Steel

- Nylon

- T303 - stainless steel

- T316 - stainless steel

- UMHW - polyethylene plastic

Nose Roll Sizing

The minimum recommended nose roll diameter for the Cleatrac® belts is 0.63" (15.9mm) for the CTB 30, 42, 48, and 60 mesh belts. Generally, use of nose rolls is not recommended with CTB 18 mesh belts.

Exception: If the application has a conveyor end-to-end distance of 10' (3 m) or less and the belt fits loosely around the conveyor, the minimum nose roll diameter may be decreased as follows:

| Mesh | Minimum Diameter in (mm) |

|---|---|

| CTB 18-16-1414 | 1 (25.4) |

| CTB 18-16-1616 | 1 (25.4) |

| CTB 30-24-1616 | 0.5 (12.7) |

| CTB 30-24-1717 | 0.5 (12.7) |

| CTB 42-36-1616 | 0.375 (9.5) |

| CTB 42-36-1717 | 0.375 (9.5) |

| CTB 42-36-1818 | 0.375 (9.5) |

| CTB 48-48-1717 | 0.25 (6.3) |

| CTB 60-48-1818 | 0.25 (6.3) |

| CTB 60-48-1820 | 0.25 (6.3) |

| CTB 60-60-1818 | 0.2 (5.1) |

| CTB 60-60-1818F | 0.2 (5.1) |

Cleatrac® Meshes

| Mesh | Thickness in. (mm) |

Lateral Pitch in. (mm) |

Opening Size (approx) |

Working Strength per Unit of Belt |

|---|---|---|---|---|

| CTB 18-16-1616 | 0.301 (7.6) | 0.67 (17.0) | 0.777 x 0.301 (inches) | 100 lb/ft (149 kg/m) |

| CTB 18-16-1414 | 0.35 (8.9) | 0.695 (17.7) | 0.855 x 0.350 (inches) | 250 lb/ft (372 kg/m) |

| CTB 30-24-1616 | 0.263 (6.7) | 0.505 (12.8) | 0.613 x 0.263 (inches) | 300 lb/ft (446 kg/m) |

| CTB 30-24-1717 | 0.287 (7.3) | 0.485 (12.3) | 0.590 x 0.287 (inches) | 200 lb/ft (298 kg/m) |

| CTB 42-36-1616 | 0.24 (6.1) | 0.35 (8.9) | 0.460 x 0.240 (inches) | 325 lb/ft (484 kg/m) |

| CTB 42-36-1717 | 0.235 (6.0) | 0.33 (8.4) | 0.435 x 0.235 (inches) | 325 lb/ft (484 kg/m) |

| CTB 42-36-1818 | 0.236 (6.0) | 0.325 (8.3) | 0.414 x 0.236 (inches) | 240 lb/ft (357 kg/m) |

| CTB 48-48-1717 | 0.24 (6.1) | 0.275 (7.0) | 0.375 x 0.240 (inches) | 450 lb/ft (670 kg/m) |

| CTB 60-48-1818 | 0.205 (5.2) | 0.26 (6.6) | 0.350 x 0.205 (inches) | 350 lb/ft (521 kg/m) |

| CTB 60-48-1820 | 0.156 (4.0) | 0.27 (6.9) | 0.326 x 0.156 (inches) | 120 lb/ft (179 kg/m) |

| CTB 60-60-1818 | 0.22 (5.6) | 0.225 (5.7) | 0.310 x 0.220 (inches) | 350 lb/ft (521 kg/m) |

| CTB 60-60-1818F | 0.22 (5.6) | 0.225 (5.7) | 0.310 x 0.220 (inches) | 350 lb/ft (521 kg/m) |

System Requirements

Application Notes

- UHMW material type components have a 150°F (66°C) maximum operation temperature.

- Molded acetal material type components have a 180°F (82°C) maximum operation temperature.

Tunnel Freezers

Use with caution as ice and snow accumulates in mesh opening or on the drive components, prohibiting sprocket teeth engagement. Install a rotary brush, or similar cleaning method, near sprocket location to minimize debris.

Soft Dough Products

Use with caution as debris may accumulate in mesh openings or on the drive components, prohibiting sprocket teeth engagement. Install a rotary brush, or similar cleaning method, near sprocket location to minimize debris.

Elevated Temperatures

Thermal expansion of the belt width may adversely affect sprocket engagement with the belt openings. If this is evident when the belt reaches application temperature, lock only the middle third of the sprockets onto the shaft so the outer sprockets can 'float' along the shaft, allowing for thermal expansion and contraction of the belt. Keep in mind that the shaft will have to be kept clean to allow sprockets to 'float'. For flour-based products in elevated temperatures, arrange the drive configuration such that a shield prevents debris from accumulating on the shaft and drive components.

Multiple Belts Driven by Common Drive Shaft

When two or more belts are driven on a common drive shaft and product alignment is critical, Ashworth Bros., Inc., must be notified at time of the purchase order is generated so that the belts will be matched. Slight differences in belt pitch can affect the alignment of the product over longer conveyor runs (typically 10ft (3m) or greater). Replacement belts for these applications require that the order reference previous purchase orders.

Number of Sprockets

The minimum number of sprockets per shaft (x) can be calculated based on the following formula:

X = Belt Width / (A + B)

Where:

A = maximum allowable spacing between sprockets

B = overall sprocket width

Fractional values should be reounded up to the next whole number.

| Mesh | (A) Max Spacing Between Sprockets in. (mm) |

Minimum Spacing in. (mm) |

|---|---|---|

| CTB 18-16-1414 | 5 (127.0) | 0.695 (17.7) |

| CTB 18-16-1616 | 5 (127.0) | 0.67 (17.0) |

| CTB 30-24-1616 | 3.25 (82.5) | 0.505 (12.8) |

| CTB 30-24-1717 | 3.25 (82.5) | 0.485 (12.3) |

| CTB 42-36-1616 | 3.5 (88.9) | 0.35 (8.9) |

| CTB 42-36-1717 | 3.5 (88.9) | 0.33 (8.4) |

| CTB 42-36-1818 | 3.5 (88.9) | 0.325 (8.3) |

| CTB 48-48-1717 | 3.25 (82.5) | 0.275 (7.0) |

| CTB 60-48-1818 | 3 (76.2) | 0.26 (6.6) |

| CTB 60-48-1820 | 3 (76.2) | 0.27 (6.9) |

| CTB 60-60-1818 | 3 (76.2) | 0.225 (5.7) |

| CTB 60-60-1818F | 3 (76.2) | 0.225 (5.7) |

Need more detailed information?

Need more detailed information?

Need more detailed information?

Options

Product Options

The Sprocket is Equally as Important as the Belt!

Manufactured in either UHMW polyethylene or T303 stainless steel, Cleatrac uses the perfect sprockets to positively drive mesh belting. Sprockets are available in a variety of sizes but special size sprockets may be manufactured to meet a customer’s needs.

Positive drive provides true belt travel and minimum terminal diameters allow close transfer of product onto and off belt. Sprockets are bored oversize to allow lateral movement on the shaft compensating for changes in belt width due to temperature.

Does this meet your project needs?

Does this meet your project needs?

Does this meet your project needs?

Let’s get started!

Let’s get started!

Let’s get started!

Downloads

Downloads

Installation Guides

Technical Bulletins

Conveyor System Review Form

Illustrations

-

Cleatrac Balanced Weave, CTB18-16-14

-

Cleatrac Balanced Weave, CTB30-24-17

-

Cleatrac Balanced Weave, CTB42-36-17

-

Cleatrac Balanced Weave, CTB48-48-17

-

Cleatrac Balanced Weave, CTB60-48-1820

-

Cleatrac Balanced Weave, CTB42-36-18

-

Cleatrac Balanced Weave, CTB60-60-18

-

Cleatrac Balanced Weave, CTB18-16-16

-

Cleatrac Balanced Weave, CTB60-48-18

-

Cleatrac Balanced Weave, CTB30-24-16

Features

CLEATRAC BELT & SPROCKET SYSTEM

CLEATRAC BELT & SPROCKET SYSTEM

CLEATRAC BELT & SPROCKET SYSTEM

EFFICIENT COST-EFFECTIVE

EFFICIENT COST-EFFECTIVE

POSITIVE DRIVE

STRAIGHT RUN

HYGENIC

THE INDUSTRY'S

TIGHTEST TRANSFER

THE INDUSTRY'S TIGHTEST TRANSFER

Ashworth’s Cleatrac® belt and sprocket system is the perfect food processing solution to accurately transfer even small products, minimize product damage, and keep your manufacturing process up and running. As the industry’s only supplier of customized conical-toothed sprockets that are perfectly matched with Cleatrac belt, Cleatrac belt and sprocket systems have a proven track record in delivering the perfect pairing.

An efficient, cost-effective solution, Cleatrac Belt & Sprockets Systems are guaranteed by Ashworth to deliver positive sprocket engagement to ensure precise product conveyance throughout the processing cycle. Cleatrac belts and sprockets are also compatible with the smallest nose bar diameters in the industry, all the way down to one-fifth of an inch (5.1 millimeters)

Ashworth’s Cleatrac® belt and sprocket system is the perfect food processing solution to accurately transfer even small products, minimize product damage, and keep your manufacturing process up and running. As the industry’s only supplier of customized conical-toothed sprockets that are perfectly matched with Cleatrac belt, Cleatrac belt and sprocket systems have a proven track record in delivering the perfect pairing.

An efficient, cost-effective solution, Cleatrac Belt & Sprockets Systems are guaranteed by Ashworth to deliver positive sprocket engagement to ensure precise product conveyance throughout the processing cycle. Cleatrac belts and sprockets are also compatible with the smallest nose bar diameters in the industry, all the way down to one-fifth of an inch (5.1 millimeters)

Eliminate Belt Wavering

Guaranteed true tracking with a positive drive sprocket system

Eliminate Belt Wavering

Guaranteed true tracking with a positive drive sprocket system

CLEATRAC BELT & SPROCKET SYSTEM

AT A GLANCE

CLEATRAC BELT & SPROCKET SYSTEM

AT A GLANCE

Minimize Product Damage:

- Guaranteed positive sprocket engagement ensures precise product conveyance

- The tightest product transfer solution in the industry

- Compatible with the industry’s smallest nose bar diameters

- Sprockets designed with conical shaped teeth have no sharp points that can damage spiral wires

- Available in various mesh configurations for precise product support and airflow for a wide range of applications

Reduce Operating Costs:

- Less expensive than chain-edge construction systems

- Engineered to deliver longer belt life than pin roll drives

- More durable and less prone to fatigue than single-plane wire designs

- Constructed with an easy-to-clean open balanced weave design

On Demand Availability:

- Standard widths are in stock and available for delivery within 24 hours

- Available complete with sprockets, support bearings, and filler rolls

DIRECTION

STRAIGHT RUN

APPLICATIONS

Durable & Energy Efficient

Withstands the toughest environments with half the mass of standard flat wire

THE SPROCKET IS EQUALLY AS IMPORTANT AS THE BELT!

THE SPROCKET IS EQUALLY AS IMPORTANT AS THE BELT!

Manufactured in either UHMW polyethylene or T303 stainless steel, Cleatrac uses the perfect sprockets to positively drive mesh belting. Sprockets are available in a variety of sizes but special size sprockets may be manufactured to meet a customer’s needs.

Manufactured in either UHMW polyethylene or T303 stainless steel, Cleatrac uses the perfect sprockets to positively drive mesh belting. Sprockets are available in a variety of sizes but special size sprockets may be manufactured to meet a customer’s needs.

Positive drive provides true belt travel and minimum terminal diameters allow close transfer of product onto and off belt. Sprockets are bored oversize to allow lateral movement on the shaft compensating for changes in belt width due to temperature.

Positive drive provides true belt travel and minimum terminal diameters allow close transfer of product onto and off belt. Sprockets are bored oversize to allow lateral movement on the shaft compensating for changes in belt width due to temperature.

Improved Can Stability

Smooth even surface for tight can transfers

Does this meet your project needs?

Does this meet your project needs?

Does this meet your project needs?

Let’s get started!

Let’s get started!

Let’s get started!

Specifications

Belt Calculator

Belt Weight

Working Strength

Opening Size

Open Area Surface

Open Area Thru

Min Nose Diameter

Thickness

Available Sprocket Options

Sprocket Reference

Select another sprocket size

Select a product

| Nom. Size | Display | Teeth | Pitch Diameter in (mm) | Hub Diameter in (mm) | Bore Min in (mm) | Bore Max in (mm) |

|---|---|---|---|---|---|---|

| 1 | CTS 18-08 T303 | 8 | 1.75 (44.42) | 1.51 (38.38) | 0 | 1.08 (27.43) |

| 1 | CTS 18-08 UHMW | 8 | 1.75 (44.42) | 1.51 (38.38) | 0.25 (6.35) | 1 (25.4) |

| 1 | CTS 18-08 UHMW | 8 | 1.75 (44.42) | 1.51 (38.38) | 0.5 (12.7) | 1 (25.4) |

| 1 | CTS 18-08 UHMW | 8 | 1.75 (44.42) | 1.51 (38.38) | 0.75 (19.05) | 1 (25.4) |

| 1 | CTS 18-08 UHMW | 8 | 1.75 (44.42) | 1.51 (38.38) | 1 (25.4) | 1 (25.4) |

| 1 | CTS 30-08 T303 | 8 | 1.15 (29.29) | 0.94 (23.8) | 0 | 0.62 (15.88) |

| 1 | CTS 30-08 UHMW | 8 | 1.15 (29.29) | 0.94 (23.8) | 0.25 (6.35) | 0.62 (15.88) |

| 1 | CTS 30-08 UHMW | 8 | 1.15 (29.29) | 0.94 (23.8) | 0.5 (12.7) | 0.62 (15.88) |

| 1 | CTS 30-08 UHMW | 8 | 1.15 (29.29) | 0.94 (23.8) | 0.5 (12.7) | 0.62 (15.88) |

| 1 | CTS 30-08 UHMW | 8 | 1.15 (29.29) | 0.94 (23.8) | 0.62 (15.88) | 0.62 (15.88) |

| 1 | CTS 42-12 T303 SS | 12 | 1.19 (30.23) | 1 (25.5) | 0.5 (12.7) | 0.63 (16) |

| 1 | CTS 42-12 UHMW | 12 | 1.2 (30.38) | 1.01 (25.73) | 0.5 (12.7) | 0.5 (12.7) |

| 1 | CTS 42-12 UHMW | 12 | 1.2 (30.38) | 1.01 (25.73) | 0.5 (12.7) | 0.5 (12.7) |

| 1 | CTS 48-20 T303 SS | 20 | 1.52 (38.73) | 1.34 (34.01) | 0 | 0.96 (24.38) |

| 1 | CTS 48-20 UHMW | 20 | 1.52 (38.73) | 1.34 (34.01) | 0.5 (12.7) | 0.72 (18.29) |

| 1 | CTS 60-08 UHMW | 8 | 0.56 (14.2) | 0.43 (11.02) | 0.24 (5.99) | 0.25 (6.35) |

| 1 | CTS 60-08 UHMW | 8 | 0.56 (14.2) | 0.43 (11.02) | 0.2 (5.08) | 0.25 (6.35) |

| 1 | CTS 60-08 UHMW | 8 | 0.56 (14.2) | 0.43 (11.02) | 0.25 (6.35) | 0.25 (6.35) |

| 1 | CTS 60-28 T303 SS | 28 | 1.73 (43.89) | 1.57 (39.95) | 0.69 (17.53) | 1.14 (28.96) |

| 1 | CTS 60-28 UHMW | 28 | 1.73 (43.89) | 1.57 (39.95) | 0.75 (19.05) | 0.95 (24.13) |

| 1 | CTS60-28 T303 | 28 | 1.73 (43.89) | 1.57 (39.95) | 0 | 1.14 (28.96) |

| 2 | CTS 18-12 Acetal | 12 | 2.74 (69.55) | 2.5 (63.5) | 0.75 (19.05) | 1.88 (47.75) |

| 2 | CTS 18-12 T303 | 12 | 2.74 (69.55) | 2.5 (63.5) | 0.69 (17.53) | 1.88 (47.75) |

| 2 | CTS 18-12 UHMW | 12 | 2.74 (69.55) | 2.5 (63.5) | 1 (25.4) | 1.69 (42.93) |

| 2 | CTS 18-12 UHMW Blue | 12 | 2.74 (69.55) | 2.5 (63.5) | 0.75 (19.05) | 1.69 (42.93) |

| 2 | CTS 30-12 Acetal | 12 | 1.81 (46.02) | 1.6 (40.54) | 1 (25.4) | 1 (25.4) |

| 2 | CTS 30-12 T303 | 12 | 1.81 (46.02) | 1.6 (40.54) | 0.69 (17.53) | 1.16 (29.46) |

| 2 | CTS 30-12 UHMW | 12 | 1.81 (46.02) | 1.6 (40.54) | 0.25 (6.35) | 1 (25.4) |

| 2 | CTS 30-12 UHMW | 12 | 1.81 (46.02) | 1.6 (40.54) | 0.5 (12.7) | 1 (25.4) |

| 2 | CTS 30-12 UHMW | 12 | 1.81 (46.02) | 1.6 (40.54) | 0.75 (19.05) | 1 (25.4) |

| 2 | CTS 30-12 UHMW | 12 | 1.81 (46.02) | 1.6 (40.54) | 0.75 (19.05) | 1 (25.4) |

| 2 | CTS 30-12 UHMW | 12 | 1.81 (46.02) | 1.6 (40.54) | 1 (25.4) | 1 (25.4) |

| 2 | CTS 30-12 UHMW | 12 | 1.81 (46.02) | 1.6 (40.54) | 1 (25.4) | 1 (25.4) |

| 2 | CTS 42-20 T303 SS | 20 | 2.07 (52.48) | 1.88 (47.75) | 1 (25.4) | 1.38 (35.05) |

| 2 | CTS 42-20 T303 SS | 20 | 2.07 (52.48) | 1.88 (47.75) | 0 | 1.38 (35.05) |

| 2 | CTS 42-20 UHMW | 20 | 2.05 (52.07) | 1.88 (47.75) | 0.75 (19.05) | 1.19 (30.23) |

| 2 | CTS 42-20 UHMW | 20 | 2.05 (52.07) | 1.88 (47.75) | 1 (25.4) | 1.19 (30.23) |

| 2 | CTS 42-20 UHMW | 20 | 2.05 (52.07) | 1.88 (47.75) | 1 (25.4) | 1.19 (30.23) |

| 2 | CTS 48-24 T303 SS | 24 | 1.85 (46.86) | 1.66 (42.14) | 0 | 1.22 (30.99) |

| 2 | CTS 48-24 UHMW | 24 | 1.85 (46.86) | 1.66 (42.14) | 0.75 (19.05) | 0.97 (24.64) |

| 2 | CTS 60-12 T303 SS | 12 | 0.9 (22.81) | 0.77 (19.63) | 0.5 (12.7) | 0.5 (12.7) |

| 2 | CTS 60-12 T303 SS | 12 | 0.9 (22.81) | 0.77 (19.63) | 0 | 0.43 (10.92) |

| 2 | CTS 60-12 UHMW | 12 | 0.9 (22.81) | 0.77 (19.63) | 0.25 (6.35) | 0.5 (12.7) |

| 2 | CTS 60-12 UHMW | 12 | 0.9 (22.81) | 0.77 (19.63) | 0.5 (12.7) | 0.5 (12.7) |

| 2 | CTS 60-40 T303 SS | 40 | 2.49 (63.3) | 2.34 (59.41) | 0.69 (17.53) | 1.78 (45.21) |

| 2 | CTS 60-40 UHMW | 40 | 2.49 (63.3) | 2.34 (59.41) | 0.75 (19.05) | 1.53 (38.86) |

| 2 | CTS 60-40 UHMW | 40 | 2.49 (63.3) | 2.34 (59.41) | 0.75 (19.05) | 1.53 (38.86) |

| 2 | CTS 60-40 UHMW | 40 | 2.49 (63.3) | 2.34 (59.41) | 1 (25.4) | 1.53 (38.86) |

| 2 | CTS 60-40 UHMW Blue | 40 | 2.49 (63.3) | 2.34 (59.41) | 1 (25.4) | 1.53 (38.86) |

| 3 | CTS 18-14 Acetal | 14 | 3.21 (81.46) | 2.95 (74.98) | 1.5 (38.1) | 2.33 (59.18) |

| 3 | CTS 18-14 T303 | 14 | 3.2 (81.2) | 2.99 (75.84) | 0 | 0 |

| 3 | CTS 18-14 UHMW | 14 | 3.21 (81.46) | 2.95 (74.98) | 0.5 (12.7) | 2.08 (52.83) |

| 3 | CTS 30-14 T303 | 14 | 2.13 (54.09) | 1.91 (48.56) | 0 | 1.42 (36.07) |

| 3 | CTS 30-14 UHMW | 14 | 2.13 (54.04) | 1.93 (48.97) | 0.5 (12.7) | 1.24 (31.5) |

| 3 | CTS 42-24 T303 SS | 24 | 2.48 (63.07) | 2.3 (58.42) | 0.69 (17.53) | 1.74 (44.2) |

| 3 | CTS 42-24 UHMW | 24 | 2.48 (63.07) | 2.3 (58.42) | 0.75 (19.05) | 1.49 (37.85) |

| 3 | CTS 42-24 UHMW | 24 | 2.48 (63.07) | 2.3 (58.42) | 1 (25.4) | 1.49 (37.85) |

| 3 | CTS 48-32 T303 SS | 32 | 2.48 (63.06) | 2.31 (58.67) | 0.69 (17.46) | 1.75 (44.45) |

| 3 | CTS 48-32 UHMW | 32 | 2.48 (63.06) | 2.31 (58.67) | 0.75 (19.05) | 1.5 (38.1) |

| 3 | CTS 48-32 UHMW | 32 | 2.48 (63.06) | 2.31 (58.67) | 1 (25.4) | 1.5 (38.1) |

| 3 | CTS 60-14 UHMW | 14 | 1.05 (26.64) | 0.89 (22.63) | 0.5 (12.7) | 0.5 (12.7) |

| 3 | CTS 60-92 T303 SS | 92 | 5.81 (147.52) | 5.64 (143.15) | 0.69 (17.53) | 4.52 (114.81) |

| 3 | CTS 60-92 UHMW | 92 | 5.81 (147.52) | 5.64 (143.15) | 0.75 (19.05) | 4.28 (108.71) |

| 3 | CTS 60-92 UHMW | 92 | 5.81 (147.52) | 5.64 (143.15) | 1 (25.4) | 4.28 (108.71) |

| 3 | CTS 60-92 UHMW | 92 | 5.81 (147.52) | 5.64 (143.15) | 1 (25.4) | 4.28 (108.71) |

| 3 | CTS 60-92 UHMW | 92 | 5.64 (143.15) | 5.81 (147.52) | 1.25 (31.75) | 4.45 (113.03) |

| 3 | CTS 60-92 UHMW Blue | 92 | 5.81 (147.52) | 5.64 (143.15) | 0.75 (19.05) | 4.28 (108.71) |

| 3 | CTS 60-92 UHMW Blue | 92 | 5.81 (147.52) | 5.64 (143.15) | 1 (25.4) | 4.28 (108.71) |

| 4 | CTS 18-18 T303 | 18 | 3.95 (100.37) | 3.95 (100.3) | 0 | 3.08 (78.23) |

| 4 | CTS 18-18 UHMW | 18 | 4.19 (106.48) | 3.95 (100.43) | 1.18 (29.97) | 2.96 (75.18) |

| 4 | CTS 18-18 UHMW | 18 | 4.19 (106.48) | 3.95 (100.43) | 0.5 (12.7) | 2.96 (75.18) |

| 4 | CTS 18-18 UHMW | 18 | 4.19 (106.48) | 3.95 (100.43) | 0.75 (19.05) | 2.96 (75.18) |

| 4 | CTS 18-18 UHMW | 18 | 4.19 (106.48) | 3.95 (100.43) | 1 (25.4) | 2.96 (75.18) |

| 4 | CTS 30-16 T303 | 16 | 2.45 (62.28) | 2.23 (56.74) | 0 | 1.68 (42.67) |

| 4 | CTS 30-16 UHMW | 16 | 2.44 (62.05) | 2.23 (56.57) | 0.75 (19.05) | 1.48 (37.59) |

| 4 | CTS 42-30 T303 SS | 30 | 3.11 (79.11) | 2.93 (74.5) | 0 | 2.31 (58.67) |

| 4 | CTS 42-30 UHMW | 30 | 3.12 (79.12) | 2.93 (74.4) | 1 (25.4) | 2.06 (52.32) |

| 4 | CTS 48-48 T303 SS | 48 | 3.88 (98.63) | 3.7 (93.9) | 1.94 (49.21) | 2.95 (74.93) |

| 4 | CTS 60-24 Acetal | 24 | 1.86 (47.35) | 1.74 (44.17) | 0.92 (23.37) | 1.3 (33.02) |

| 4 | CTS 60-24 ACETAL | 24 | 1.86 (47.35) | 1.74 (44.17) | 0.66 (16.76) | 1.3 (33.02) |

| 4 | CTS 60-24 T303 SS | 24 | 1.86 (47.35) | 1.74 (44.17) | 0.69 (17.53) | 1.3 (33.02) |

| 4 | CTS 60-24 T316 SS | 24 | 1.86 (47.35) | 1.74 (44.17) | 1 (25.4) | 1.3 (33.02) |

| 4 | CTS 60-24 UHMW | 24 | 1.86 (47.35) | 1.74 (44.17) | 0.75 (19.05) | 1.05 (26.67) |

| 4 | CTS 60-24 UHMW | 24 | 1.86 (47.35) | 1.74 (44.17) | 0.75 (19.05) | 1.05 (26.67) |

| 4 | CTS 60-24 UHMW | 24 | 1.86 (47.35) | 1.74 (44.17) | 1 (25.4) | 1.05 (26.67) |

| 5 | CTS 18-20 Acetal | 20 | 4.67 (118.72) | 4.43 (112.65) | 1.58 (40.01) | 3.45 (87.63) |

| 5 | CTS 18-20 UHMW | 20 | 4.67 (118.72) | 4.43 (112.65) | 0.75 (19.05) | 3.32 (84.33) |

| 5 | CTS 30-18 T303 SS | 18 | 2.77 (70.46) | 2.56 (64.92) | 0 | 1.94 (49.28) |

| 5 | CTS 30-18 UHMW | 18 | 2.79 (70.92) | 2.58 (65.43) | 0.75 (19.05) | 1.77 (44.96) |

| 5 | CTS 30-18 UHMW | 18 | 2.79 (70.92) | 2.58 (65.43) | 1 (25.4) | 1.77 (44.96) |

| 5 | CTS 30-18 UHMW | 18 | 2.79 (70.92) | 2.58 (65.43) | 1 (25.4) | 1.77 (44.96) |

| 5 | CTS 42-32 T303 SS | 32 | 3.3 (83.76) | 3.12 (79.3) | 1.97 (50.01) | 2.38 (60.45) |

| 5 | CTS 42-32 T303 SS | 32 | 3.3 (83.76) | 3.12 (79.3) | 1 (25.4) | 2.38 (60.45) |

| 5 | CTS 42-32 T303 SS | 32 | 3.3 (83.76) | 3.12 (79.3) | 1.25 (31.75) | 2.38 (60.45) |

| 5 | CTS 42-32 T303 SS | 32 | 3.3 (83.76) | 3.12 (79.3) | 0.69 (17.46) | 2.38 (60.45) |

| 5 | CTS 42-32 UHMW | 32 | 3.33 (84.61) | 3.14 (79.88) | 0.75 (19.05) | 2.27 (57.66) |

| 5 | CTS 42-32 UHMW | 32 | 3.33 (84.61) | 3.14 (79.88) | 1 (25.4) | 2.27 (57.66) |

| 5 | CTS 48-74 T303 SS | 74 | 6.02 (152.93) | 5.84 (148.21) | 1 (25.4) | 4.72 (119.89) |

| 5 | CTS 60-42 T303 SS | 42 | 3.29 (83.57) | 3.16 (80.31) | 0.69 (17.53) | 2.42 (61.47) |

| 5 | CTS 60-42 T303 SS | 42 | 3.29 (83.57) | 3.16 (80.31) | 0 | 2.42 (61.47) |

| 5 | CTS 60-42 UHMW | 42 | 3.29 (83.57) | 3.16 (80.31) | 1 (25.4) | 2.29 (58.17) |

| 5 | CTS 60-42 UHMW | 42 | 3.29 (83.57) | 3.16 (80.31) | 0.75 (19.05) | 2.29 (58.17) |

| 5 | CTS 60-42 UHMW | 42 | 3.29 (83.57) | 3.16 (80.31) | 1 (25.4) | 2.29 (58.17) |

| 6 | CTS 30-20 T303 | 20 | 3.11 (78.99) | 2.89 (73.33) | 0.69 (17.53) | 2.27 (57.66) |

| 6 | CTS 30-20 UHMW | 20 | 3.11 (78.99) | 2.89 (73.33) | 0.75 (19.05) | 2.02 (51.31) |

| 6 | CTS 30-20 UHMW | 20 | 3.11 (78.99) | 2.89 (73.33) | 1 (25.4) | 2.02 (51.31) |

| 6 | CTS 30-20 UHMW | 20 | 3.11 (78.99) | 2.89 (73.33) | 1 (25.4) | 2.02 (51.31) |

| 6 | CTS 30-20 UHMW | 20 | 3.11 (78.99) | 2.89 (73.33) | 1.75 (44.45) | 2.02 (51.31) |

| 6 | CTS 42-40 T303 SS | 40 | 4.18 (106.22) | 4 (101.5) | 0 | 3.13 (79.5) |

| 6 | CTS 42-40 T303 SS | 40 | 4.18 (106.22) | 4 (101.5) | 1 (25.4) | 3.13 (79.5) |

| 6 | CTS 42-40 T303 SS | 40 | 4.18 (106.22) | 4 (101.5) | 0 | 3.13 (79.5) |

| 6 | CTS 42-40 UHMW | 40 | 4.18 (106.27) | 4 (101.5) | 0.5 (12.7) | 3 (76.2) |

| 6 | CTS 42-40 UHMW | 40 | 4.18 (106.27) | 4 (101.5) | 1 (25.4) | 3 (76.2) |

| 6 | CTS 42-40 UHMW | 40 | 4.18 (106.27) | 4 (101.5) | 1.25 (31.75) | 3 (76.2) |

| 6 | CTS 60-54 T303 SS | 54 | 4.24 (107.82) | 4.09 (103.96) | 0.69 (17.53) | 3.23 (82.04) |

| 6 | CTS 60-54 UHMW | 54 | 4.24 (107.82) | 4.09 (103.96) | 1 (25.4) | 2.98 (75.69) |

| 7 | CTS 30-22 UHMW | 22 | 3.42 (86.77) | 3.2 (81.23) | 1.5 (38.1) | 2.33 (59.18) |

| 7 | CTS 42-56 T303 SS | 56 | 5.88 (149.28) | 5.7 (144.68) | 0 | 4.58 (116.33) |

| 7 | CTS 42-56 UHMW | 56 | 5.88 (149.28) | 5.7 (144.68) | 1 (25.4) | 4.34 (110.24) |

| 7 | CTS 60-82 T303 SS | 82 | 6.45 (163.78) | 6.32 (160.6) | 0.75 (19.05) | 5.09 (129.29) |

| 7 | CTS 60-82 UHMW | 82 | 6.47 (164.46) | 6.32 (160.6) | 0.75 (19.05) | 4.84 (122.94) |

| 7 | CTS 60-82 UHMW | 82 | 6.47 (164.46) | 6.32 (160.6) | 1 (25.4) | 4.84 (122.94) |

| 7 | CTS 60-82 UHMW Blue | 82 | 6.47 (164.46) | 6.32 (160.6) | 0.75 (19.05) | 4.84 (122.94) |

| 8 | CTS 30-24 T303 | 24 | 3.74 (95.1) | 3.54 (89.81) | 0 | 2.79 (70.87) |

| 8 | CTS 30-24 T316L | 24 | 3.74 (95.1) | 3.54 (89.81) | 0 | 2.79 (70.87) |

| 8 | CTS 30-24 UHMW | 24 | 3.74 (95.12) | 3.52 (89.51) | 1 (25.4) | 2.53 (64.26) |

| 9 | CTS 30-26 T303 | 26 | 4.07 (103.25) | 3.84 (97.64) | 0.69 (17.53) | 2.98 (75.69) |

| 9 | CTS 30-26 UHMW | 26 | 4.07 (103.25) | 3.84 (97.64) | 0.75 (19.05) | 2.85 (72.39) |

| 10 | CTS 30-30 UHMW | 30 | 4.7 (119.28) | 4.49 (114.17) | 2.76 (70) | 3.38 (85.85) |

| 10 | CTS 30-30 UHMW | 30 | 4.7 (119.28) | 4.49 (114.17) | 0.75 (19.05) | 3.38 (85.85) |

| 11 | CTS 30-40 T303 | 40 | 6.29 (159.84) | 6.09 (154.71) | 0 | 4.86 (123.44) |

Material Reference

- Acetal - polyoxymethylene plastic

- Celcon - acetal copolymer

- CI - cast iron

- Hardened Steel

- Nylon

- T303 - stainless steel

- T316 - stainless steel

- UMHW - polyethylene plastic

Nose Roll Sizing

The minimum recommended nose roll diameter for the Cleatrac® belts is 0.63" (15.9mm) for the CTB 30, 42, 48, and 60 mesh belts. Generally, use of nose rolls is not recommended with CTB 18 mesh belts.

Exception: If the application has a conveyor end-to-end distance of 10' (3 m) or less and the belt fits loosely around the conveyor, the minimum nose roll diameter may be decreased as follows:

| Mesh | Minimum Diameter in (mm) |

|---|---|

| CTB 18-16-1414 | 1 (25.4) |

| CTB 18-16-1616 | 1 (25.4) |

| CTB 30-24-1616 | 0.5 (12.7) |

| CTB 30-24-1717 | 0.5 (12.7) |

| CTB 42-36-1616 | 0.375 (9.5) |

| CTB 42-36-1717 | 0.375 (9.5) |

| CTB 42-36-1818 | 0.375 (9.5) |

| CTB 48-48-1717 | 0.25 (6.3) |

| CTB 60-48-1818 | 0.25 (6.3) |

| CTB 60-48-1820 | 0.25 (6.3) |

| CTB 60-60-1818 | 0.2 (5.1) |

| CTB 60-60-1818F | 0.2 (5.1) |

Cleatrac® Meshes

| Mesh | Thickness in. (mm) |

Lateral Pitch in. (mm) |

Opening Size (approx) |

Working Strength per Unit of Belt |

|---|---|---|---|---|

| CTB 18-16-1616 | 0.301 (7.6) | 0.67 (17.0) | 0.777 x 0.301 (inches) | 100 lb/ft (149 kg/m) |

| CTB 18-16-1414 | 0.35 (8.9) | 0.695 (17.7) | 0.855 x 0.350 (inches) | 250 lb/ft (372 kg/m) |

| CTB 30-24-1616 | 0.263 (6.7) | 0.505 (12.8) | 0.613 x 0.263 (inches) | 300 lb/ft (446 kg/m) |

| CTB 30-24-1717 | 0.287 (7.3) | 0.485 (12.3) | 0.590 x 0.287 (inches) | 200 lb/ft (298 kg/m) |

| CTB 42-36-1616 | 0.24 (6.1) | 0.35 (8.9) | 0.460 x 0.240 (inches) | 325 lb/ft (484 kg/m) |

| CTB 42-36-1717 | 0.235 (6.0) | 0.33 (8.4) | 0.435 x 0.235 (inches) | 325 lb/ft (484 kg/m) |

| CTB 42-36-1818 | 0.236 (6.0) | 0.325 (8.3) | 0.414 x 0.236 (inches) | 240 lb/ft (357 kg/m) |

| CTB 48-48-1717 | 0.24 (6.1) | 0.275 (7.0) | 0.375 x 0.240 (inches) | 450 lb/ft (670 kg/m) |

| CTB 60-48-1818 | 0.205 (5.2) | 0.26 (6.6) | 0.350 x 0.205 (inches) | 350 lb/ft (521 kg/m) |

| CTB 60-48-1820 | 0.156 (4.0) | 0.27 (6.9) | 0.326 x 0.156 (inches) | 120 lb/ft (179 kg/m) |

| CTB 60-60-1818 | 0.22 (5.6) | 0.225 (5.7) | 0.310 x 0.220 (inches) | 350 lb/ft (521 kg/m) |

| CTB 60-60-1818F | 0.22 (5.6) | 0.225 (5.7) | 0.310 x 0.220 (inches) | 350 lb/ft (521 kg/m) |

System Requirements

Application Notes

- UHMW material type components have a 150°F (66°C) maximum operation temperature.

- Molded acetal material type components have a 180°F (82°C) maximum operation temperature.

Tunnel Freezers

Use with caution as ice and snow accumulates in mesh opening or on the drive components, prohibiting sprocket teeth engagement. Install a rotary brush, or similar cleaning method, near sprocket location to minimize debris.

Soft Dough Products

Use with caution as debris may accumulate in mesh openings or on the drive components, prohibiting sprocket teeth engagement. Install a rotary brush, or similar cleaning method, near sprocket location to minimize debris.

Elevated Temperatures

Thermal expansion of the belt width may adversely affect sprocket engagement with the belt openings. If this is evident when the belt reaches application temperature, lock only the middle third of the sprockets onto the shaft so the outer sprockets can 'float' along the shaft, allowing for thermal expansion and contraction of the belt. Keep in mind that the shaft will have to be kept clean to allow sprockets to 'float'. For flour-based products in elevated temperatures, arrange the drive configuration such that a shield prevents debris from accumulating on the shaft and drive components.

Multiple Belts Driven by Common Drive Shaft

When two or more belts are driven on a common drive shaft and product alignment is critical, Ashworth Bros., Inc., must be notified at time of the purchase order is generated so that the belts will be matched. Slight differences in belt pitch can affect the alignment of the product over longer conveyor runs (typically 10ft (3m) or greater). Replacement belts for these applications require that the order reference previous purchase orders.

Number of Sprockets

The minimum number of sprockets per shaft (x) can be calculated based on the following formula:

X = Belt Width / (A + B)

Where:

A = maximum allowable spacing between sprockets

B = overall sprocket width

Fractional values should be reounded up to the next whole number.

| Mesh | (A) Max Spacing Between Sprockets in. (mm) |

Minimum Spacing in. (mm) |

|---|---|---|

| CTB 18-16-1414 | 5 (127.0) | 0.695 (17.7) |

| CTB 18-16-1616 | 5 (127.0) | 0.67 (17.0) |

| CTB 30-24-1616 | 3.25 (82.5) | 0.505 (12.8) |

| CTB 30-24-1717 | 3.25 (82.5) | 0.485 (12.3) |

| CTB 42-36-1616 | 3.5 (88.9) | 0.35 (8.9) |

| CTB 42-36-1717 | 3.5 (88.9) | 0.33 (8.4) |

| CTB 42-36-1818 | 3.5 (88.9) | 0.325 (8.3) |

| CTB 48-48-1717 | 3.25 (82.5) | 0.275 (7.0) |

| CTB 60-48-1818 | 3 (76.2) | 0.26 (6.6) |

| CTB 60-48-1820 | 3 (76.2) | 0.27 (6.9) |

| CTB 60-60-1818 | 3 (76.2) | 0.225 (5.7) |

| CTB 60-60-1818F | 3 (76.2) | 0.225 (5.7) |

Need more detailed information?

Need more detailed information?

Need more detailed information?

Options

Product Options

The Sprocket is Equally as Important as the Belt!

Manufactured in either UHMW polyethylene or T303 stainless steel, Cleatrac uses the perfect sprockets to positively drive mesh belting. Sprockets are available in a variety of sizes but special size sprockets may be manufactured to meet a customer’s needs.

Positive drive provides true belt travel and minimum terminal diameters allow close transfer of product onto and off belt. Sprockets are bored oversize to allow lateral movement on the shaft compensating for changes in belt width due to temperature.

Does this meet your project needs?

Does this meet your project needs?

Does this meet your project needs?

Let’s get started!

Let’s get started!

Let’s get started!

Downloads

Downloads

Installation Guides

Technical Bulletins

Conveyor System Review Form

Illustrations

-

Cleatrac Balanced Weave, CTB18-16-14

-

Cleatrac Balanced Weave, CTB30-24-17

-

Cleatrac Balanced Weave, CTB42-36-17

-

Cleatrac Balanced Weave, CTB48-48-17

-

Cleatrac Balanced Weave, CTB60-48-1820

-

Cleatrac Balanced Weave, CTB42-36-18

-

Cleatrac Balanced Weave, CTB60-60-18

-

Cleatrac Balanced Weave, CTB18-16-16

-

Cleatrac Balanced Weave, CTB60-48-18

-

Cleatrac Balanced Weave, CTB30-24-16

Features

CLEATRAC BELT & SPROCKET SYSTEM

CLEATRAC BELT & SPROCKET SYSTEM

CLEATRAC BELT & SPROCKET SYSTEM

EFFICIENT COST-EFFECTIVE

EFFICIENT COST-EFFECTIVE

POSITIVE DRIVE

STRAIGHT RUN

HYGENIC

THE INDUSTRY'S

TIGHTEST TRANSFER

THE INDUSTRY'S TIGHTEST TRANSFER

Ashworth’s Cleatrac® belt and sprocket system is the perfect food processing solution to accurately transfer even small products, minimize product damage, and keep your manufacturing process up and running. As the industry’s only supplier of customized conical-toothed sprockets that are perfectly matched with Cleatrac belt, Cleatrac belt and sprocket systems have a proven track record in delivering the perfect pairing.

An efficient, cost-effective solution, Cleatrac Belt & Sprockets Systems are guaranteed by Ashworth to deliver positive sprocket engagement to ensure precise product conveyance throughout the processing cycle. Cleatrac belts and sprockets are also compatible with the smallest nose bar diameters in the industry, all the way down to one-fifth of an inch (5.1 millimeters)

Ashworth’s Cleatrac® belt and sprocket system is the perfect food processing solution to accurately transfer even small products, minimize product damage, and keep your manufacturing process up and running. As the industry’s only supplier of customized conical-toothed sprockets that are perfectly matched with Cleatrac belt, Cleatrac belt and sprocket systems have a proven track record in delivering the perfect pairing.

An efficient, cost-effective solution, Cleatrac Belt & Sprockets Systems are guaranteed by Ashworth to deliver positive sprocket engagement to ensure precise product conveyance throughout the processing cycle. Cleatrac belts and sprockets are also compatible with the smallest nose bar diameters in the industry, all the way down to one-fifth of an inch (5.1 millimeters)

Eliminate Belt Wavering

Guaranteed true tracking with a positive drive sprocket system

Eliminate Belt Wavering

Guaranteed true tracking with a positive drive sprocket system

CLEATRAC BELT & SPROCKET SYSTEM

AT A GLANCE

CLEATRAC BELT & SPROCKET SYSTEM

AT A GLANCE

Minimize Product Damage:

- Guaranteed positive sprocket engagement ensures precise product conveyance

- The tightest product transfer solution in the industry

- Compatible with the industry’s smallest nose bar diameters

- Sprockets designed with conical shaped teeth have no sharp points that can damage spiral wires

- Available in various mesh configurations for precise product support and airflow for a wide range of applications

Reduce Operating Costs:

- Less expensive than chain-edge construction systems

- Engineered to deliver longer belt life than pin roll drives

- More durable and less prone to fatigue than single-plane wire designs

- Constructed with an easy-to-clean open balanced weave design

On Demand Availability:

- Standard widths are in stock and available for delivery within 24 hours

- Available complete with sprockets, support bearings, and filler rolls

DIRECTION

STRAIGHT RUN

APPLICATIONS

Durable & Energy Efficient

Withstands the toughest environments with half the mass of standard flat wire

THE SPROCKET IS EQUALLY AS IMPORTANT AS THE BELT!

THE SPROCKET IS EQUALLY AS IMPORTANT AS THE BELT!

Manufactured in either UHMW polyethylene or T303 stainless steel, Cleatrac uses the perfect sprockets to positively drive mesh belting. Sprockets are available in a variety of sizes but special size sprockets may be manufactured to meet a customer’s needs.

Manufactured in either UHMW polyethylene or T303 stainless steel, Cleatrac uses the perfect sprockets to positively drive mesh belting. Sprockets are available in a variety of sizes but special size sprockets may be manufactured to meet a customer’s needs.

Positive drive provides true belt travel and minimum terminal diameters allow close transfer of product onto and off belt. Sprockets are bored oversize to allow lateral movement on the shaft compensating for changes in belt width due to temperature.

Positive drive provides true belt travel and minimum terminal diameters allow close transfer of product onto and off belt. Sprockets are bored oversize to allow lateral movement on the shaft compensating for changes in belt width due to temperature.

Improved Can Stability

Smooth even surface for tight can transfers

Does this meet your project needs?

Does this meet your project needs?

Does this meet your project needs?

Let’s get started!

Let’s get started!

Let’s get started!

Specifications

Belt Calculator

Belt Weight

Working Strength

Opening Size

Open Area Surface

Open Area Thru

Min Nose Diameter

Thickness

Available Sprocket Options

Sprocket Reference

Select another sprocket size

Select a product

| Nom. Size | Display | Teeth | Pitch Diameter in (mm) | Hub Diameter in (mm) | Bore Min in (mm) | Bore Max in (mm) |

|---|---|---|---|---|---|---|

| 1 | CTS 18-08 T303 | 8 | 1.75 (44.42) | 1.51 (38.38) | 0 | 1.08 (27.43) |

| 1 | CTS 18-08 UHMW | 8 | 1.75 (44.42) | 1.51 (38.38) | 0.25 (6.35) | 1 (25.4) |

| 1 | CTS 18-08 UHMW | 8 | 1.75 (44.42) | 1.51 (38.38) | 0.5 (12.7) | 1 (25.4) |

| 1 | CTS 18-08 UHMW | 8 | 1.75 (44.42) | 1.51 (38.38) | 0.75 (19.05) | 1 (25.4) |

| 1 | CTS 18-08 UHMW | 8 | 1.75 (44.42) | 1.51 (38.38) | 1 (25.4) | 1 (25.4) |

| 1 | CTS 30-08 T303 | 8 | 1.15 (29.29) | 0.94 (23.8) | 0 | 0.62 (15.88) |

| 1 | CTS 30-08 UHMW | 8 | 1.15 (29.29) | 0.94 (23.8) | 0.25 (6.35) | 0.62 (15.88) |

| 1 | CTS 30-08 UHMW | 8 | 1.15 (29.29) | 0.94 (23.8) | 0.5 (12.7) | 0.62 (15.88) |

| 1 | CTS 30-08 UHMW | 8 | 1.15 (29.29) | 0.94 (23.8) | 0.5 (12.7) | 0.62 (15.88) |

| 1 | CTS 30-08 UHMW | 8 | 1.15 (29.29) | 0.94 (23.8) | 0.62 (15.88) | 0.62 (15.88) |

| 1 | CTS 42-12 T303 SS | 12 | 1.19 (30.23) | 1 (25.5) | 0.5 (12.7) | 0.63 (16) |

| 1 | CTS 42-12 UHMW | 12 | 1.2 (30.38) | 1.01 (25.73) | 0.5 (12.7) | 0.5 (12.7) |

| 1 | CTS 42-12 UHMW | 12 | 1.2 (30.38) | 1.01 (25.73) | 0.5 (12.7) | 0.5 (12.7) |

| 1 | CTS 48-20 T303 SS | 20 | 1.52 (38.73) | 1.34 (34.01) | 0 | 0.96 (24.38) |

| 1 | CTS 48-20 UHMW | 20 | 1.52 (38.73) | 1.34 (34.01) | 0.5 (12.7) | 0.72 (18.29) |

| 1 | CTS 60-08 UHMW | 8 | 0.56 (14.2) | 0.43 (11.02) | 0.24 (5.99) | 0.25 (6.35) |

| 1 | CTS 60-08 UHMW | 8 | 0.56 (14.2) | 0.43 (11.02) | 0.2 (5.08) | 0.25 (6.35) |

| 1 | CTS 60-08 UHMW | 8 | 0.56 (14.2) | 0.43 (11.02) | 0.25 (6.35) | 0.25 (6.35) |

| 1 | CTS 60-28 T303 SS | 28 | 1.73 (43.89) | 1.57 (39.95) | 0.69 (17.53) | 1.14 (28.96) |

| 1 | CTS 60-28 UHMW | 28 | 1.73 (43.89) | 1.57 (39.95) | 0.75 (19.05) | 0.95 (24.13) |

| 1 | CTS60-28 T303 | 28 | 1.73 (43.89) | 1.57 (39.95) | 0 | 1.14 (28.96) |

| 2 | CTS 18-12 Acetal | 12 | 2.74 (69.55) | 2.5 (63.5) | 0.75 (19.05) | 1.88 (47.75) |

| 2 | CTS 18-12 T303 | 12 | 2.74 (69.55) | 2.5 (63.5) | 0.69 (17.53) | 1.88 (47.75) |

| 2 | CTS 18-12 UHMW | 12 | 2.74 (69.55) | 2.5 (63.5) | 1 (25.4) | 1.69 (42.93) |

| 2 | CTS 18-12 UHMW Blue | 12 | 2.74 (69.55) | 2.5 (63.5) | 0.75 (19.05) | 1.69 (42.93) |

| 2 | CTS 30-12 Acetal | 12 | 1.81 (46.02) | 1.6 (40.54) | 1 (25.4) | 1 (25.4) |

| 2 | CTS 30-12 T303 | 12 | 1.81 (46.02) | 1.6 (40.54) | 0.69 (17.53) | 1.16 (29.46) |

| 2 | CTS 30-12 UHMW | 12 | 1.81 (46.02) | 1.6 (40.54) | 0.25 (6.35) | 1 (25.4) |

| 2 | CTS 30-12 UHMW | 12 | 1.81 (46.02) | 1.6 (40.54) | 0.5 (12.7) | 1 (25.4) |

| 2 | CTS 30-12 UHMW | 12 | 1.81 (46.02) | 1.6 (40.54) | 0.75 (19.05) | 1 (25.4) |

| 2 | CTS 30-12 UHMW | 12 | 1.81 (46.02) | 1.6 (40.54) | 0.75 (19.05) | 1 (25.4) |

| 2 | CTS 30-12 UHMW | 12 | 1.81 (46.02) | 1.6 (40.54) | 1 (25.4) | 1 (25.4) |

| 2 | CTS 30-12 UHMW | 12 | 1.81 (46.02) | 1.6 (40.54) | 1 (25.4) | 1 (25.4) |

| 2 | CTS 42-20 T303 SS | 20 | 2.07 (52.48) | 1.88 (47.75) | 1 (25.4) | 1.38 (35.05) |

| 2 | CTS 42-20 T303 SS | 20 | 2.07 (52.48) | 1.88 (47.75) | 0 | 1.38 (35.05) |

| 2 | CTS 42-20 UHMW | 20 | 2.05 (52.07) | 1.88 (47.75) | 0.75 (19.05) | 1.19 (30.23) |

| 2 | CTS 42-20 UHMW | 20 | 2.05 (52.07) | 1.88 (47.75) | 1 (25.4) | 1.19 (30.23) |

| 2 | CTS 42-20 UHMW | 20 | 2.05 (52.07) | 1.88 (47.75) | 1 (25.4) | 1.19 (30.23) |

| 2 | CTS 48-24 T303 SS | 24 | 1.85 (46.86) | 1.66 (42.14) | 0 | 1.22 (30.99) |

| 2 | CTS 48-24 UHMW | 24 | 1.85 (46.86) | 1.66 (42.14) | 0.75 (19.05) | 0.97 (24.64) |

| 2 | CTS 60-12 T303 SS | 12 | 0.9 (22.81) | 0.77 (19.63) | 0.5 (12.7) | 0.5 (12.7) |

| 2 | CTS 60-12 T303 SS | 12 | 0.9 (22.81) | 0.77 (19.63) | 0 | 0.43 (10.92) |

| 2 | CTS 60-12 UHMW | 12 | 0.9 (22.81) | 0.77 (19.63) | 0.25 (6.35) | 0.5 (12.7) |

| 2 | CTS 60-12 UHMW | 12 | 0.9 (22.81) | 0.77 (19.63) | 0.5 (12.7) | 0.5 (12.7) |

| 2 | CTS 60-40 T303 SS | 40 | 2.49 (63.3) | 2.34 (59.41) | 0.69 (17.53) | 1.78 (45.21) |

| 2 | CTS 60-40 UHMW | 40 | 2.49 (63.3) | 2.34 (59.41) | 0.75 (19.05) | 1.53 (38.86) |

| 2 | CTS 60-40 UHMW | 40 | 2.49 (63.3) | 2.34 (59.41) | 0.75 (19.05) | 1.53 (38.86) |

| 2 | CTS 60-40 UHMW | 40 | 2.49 (63.3) | 2.34 (59.41) | 1 (25.4) | 1.53 (38.86) |

| 2 | CTS 60-40 UHMW Blue | 40 | 2.49 (63.3) | 2.34 (59.41) | 1 (25.4) | 1.53 (38.86) |

| 3 | CTS 18-14 Acetal | 14 | 3.21 (81.46) | 2.95 (74.98) | 1.5 (38.1) | 2.33 (59.18) |

| 3 | CTS 18-14 T303 | 14 | 3.2 (81.2) | 2.99 (75.84) | 0 | 0 |

| 3 | CTS 18-14 UHMW | 14 | 3.21 (81.46) | 2.95 (74.98) | 0.5 (12.7) | 2.08 (52.83) |

| 3 | CTS 30-14 T303 | 14 | 2.13 (54.09) | 1.91 (48.56) | 0 | 1.42 (36.07) |

| 3 | CTS 30-14 UHMW | 14 | 2.13 (54.04) | 1.93 (48.97) | 0.5 (12.7) | 1.24 (31.5) |

| 3 | CTS 42-24 T303 SS | 24 | 2.48 (63.07) | 2.3 (58.42) | 0.69 (17.53) | 1.74 (44.2) |

| 3 | CTS 42-24 UHMW | 24 | 2.48 (63.07) | 2.3 (58.42) | 0.75 (19.05) | 1.49 (37.85) |

| 3 | CTS 42-24 UHMW | 24 | 2.48 (63.07) | 2.3 (58.42) | 1 (25.4) | 1.49 (37.85) |

| 3 | CTS 48-32 T303 SS | 32 | 2.48 (63.06) | 2.31 (58.67) | 0.69 (17.46) | 1.75 (44.45) |

| 3 | CTS 48-32 UHMW | 32 | 2.48 (63.06) | 2.31 (58.67) | 0.75 (19.05) | 1.5 (38.1) |

| 3 | CTS 48-32 UHMW | 32 | 2.48 (63.06) | 2.31 (58.67) | 1 (25.4) | 1.5 (38.1) |

| 3 | CTS 60-14 UHMW | 14 | 1.05 (26.64) | 0.89 (22.63) | 0.5 (12.7) | 0.5 (12.7) |

| 3 | CTS 60-92 T303 SS | 92 | 5.81 (147.52) | 5.64 (143.15) | 0.69 (17.53) | 4.52 (114.81) |

| 3 | CTS 60-92 UHMW | 92 | 5.81 (147.52) | 5.64 (143.15) | 0.75 (19.05) | 4.28 (108.71) |

| 3 | CTS 60-92 UHMW | 92 | 5.81 (147.52) | 5.64 (143.15) | 1 (25.4) | 4.28 (108.71) |

| 3 | CTS 60-92 UHMW | 92 | 5.81 (147.52) | 5.64 (143.15) | 1 (25.4) | 4.28 (108.71) |

| 3 | CTS 60-92 UHMW | 92 | 5.64 (143.15) | 5.81 (147.52) | 1.25 (31.75) | 4.45 (113.03) |

| 3 | CTS 60-92 UHMW Blue | 92 | 5.81 (147.52) | 5.64 (143.15) | 0.75 (19.05) | 4.28 (108.71) |

| 3 | CTS 60-92 UHMW Blue | 92 | 5.81 (147.52) | 5.64 (143.15) | 1 (25.4) | 4.28 (108.71) |

| 4 | CTS 18-18 T303 | 18 | 3.95 (100.37) | 3.95 (100.3) | 0 | 3.08 (78.23) |

| 4 | CTS 18-18 UHMW | 18 | 4.19 (106.48) | 3.95 (100.43) | 1.18 (29.97) | 2.96 (75.18) |

| 4 | CTS 18-18 UHMW | 18 | 4.19 (106.48) | 3.95 (100.43) | 0.5 (12.7) | 2.96 (75.18) |

| 4 | CTS 18-18 UHMW | 18 | 4.19 (106.48) | 3.95 (100.43) | 0.75 (19.05) | 2.96 (75.18) |

| 4 | CTS 18-18 UHMW | 18 | 4.19 (106.48) | 3.95 (100.43) | 1 (25.4) | 2.96 (75.18) |

| 4 | CTS 30-16 T303 | 16 | 2.45 (62.28) | 2.23 (56.74) | 0 | 1.68 (42.67) |

| 4 | CTS 30-16 UHMW | 16 | 2.44 (62.05) | 2.23 (56.57) | 0.75 (19.05) | 1.48 (37.59) |

| 4 | CTS 42-30 T303 SS | 30 | 3.11 (79.11) | 2.93 (74.5) | 0 | 2.31 (58.67) |

| 4 | CTS 42-30 UHMW | 30 | 3.12 (79.12) | 2.93 (74.4) | 1 (25.4) | 2.06 (52.32) |

| 4 | CTS 48-48 T303 SS | 48 | 3.88 (98.63) | 3.7 (93.9) | 1.94 (49.21) | 2.95 (74.93) |

| 4 | CTS 60-24 Acetal | 24 | 1.86 (47.35) | 1.74 (44.17) | 0.92 (23.37) | 1.3 (33.02) |

| 4 | CTS 60-24 ACETAL | 24 | 1.86 (47.35) | 1.74 (44.17) | 0.66 (16.76) | 1.3 (33.02) |

| 4 | CTS 60-24 T303 SS | 24 | 1.86 (47.35) | 1.74 (44.17) | 0.69 (17.53) | 1.3 (33.02) |

| 4 | CTS 60-24 T316 SS | 24 | 1.86 (47.35) | 1.74 (44.17) | 1 (25.4) | 1.3 (33.02) |

| 4 | CTS 60-24 UHMW | 24 | 1.86 (47.35) | 1.74 (44.17) | 0.75 (19.05) | 1.05 (26.67) |

| 4 | CTS 60-24 UHMW | 24 | 1.86 (47.35) | 1.74 (44.17) | 0.75 (19.05) | 1.05 (26.67) |

| 4 | CTS 60-24 UHMW | 24 | 1.86 (47.35) | 1.74 (44.17) | 1 (25.4) | 1.05 (26.67) |

| 5 | CTS 18-20 Acetal | 20 | 4.67 (118.72) | 4.43 (112.65) | 1.58 (40.01) | 3.45 (87.63) |

| 5 | CTS 18-20 UHMW | 20 | 4.67 (118.72) | 4.43 (112.65) | 0.75 (19.05) | 3.32 (84.33) |

| 5 | CTS 30-18 T303 SS | 18 | 2.77 (70.46) | 2.56 (64.92) | 0 | 1.94 (49.28) |

| 5 | CTS 30-18 UHMW | 18 | 2.79 (70.92) | 2.58 (65.43) | 0.75 (19.05) | 1.77 (44.96) |

| 5 | CTS 30-18 UHMW | 18 | 2.79 (70.92) | 2.58 (65.43) | 1 (25.4) | 1.77 (44.96) |

| 5 | CTS 30-18 UHMW | 18 | 2.79 (70.92) | 2.58 (65.43) | 1 (25.4) | 1.77 (44.96) |

| 5 | CTS 42-32 T303 SS | 32 | 3.3 (83.76) | 3.12 (79.3) | 1.97 (50.01) | 2.38 (60.45) |

| 5 | CTS 42-32 T303 SS | 32 | 3.3 (83.76) | 3.12 (79.3) | 1 (25.4) | 2.38 (60.45) |

| 5 | CTS 42-32 T303 SS | 32 | 3.3 (83.76) | 3.12 (79.3) | 1.25 (31.75) | 2.38 (60.45) |

| 5 | CTS 42-32 T303 SS | 32 | 3.3 (83.76) | 3.12 (79.3) | 0.69 (17.46) | 2.38 (60.45) |

| 5 | CTS 42-32 UHMW | 32 | 3.33 (84.61) | 3.14 (79.88) | 0.75 (19.05) | 2.27 (57.66) |

| 5 | CTS 42-32 UHMW | 32 | 3.33 (84.61) | 3.14 (79.88) | 1 (25.4) | 2.27 (57.66) |

| 5 | CTS 48-74 T303 SS | 74 | 6.02 (152.93) | 5.84 (148.21) | 1 (25.4) | 4.72 (119.89) |

| 5 | CTS 60-42 T303 SS | 42 | 3.29 (83.57) | 3.16 (80.31) | 0.69 (17.53) | 2.42 (61.47) |

| 5 | CTS 60-42 T303 SS | 42 | 3.29 (83.57) | 3.16 (80.31) | 0 | 2.42 (61.47) |

| 5 | CTS 60-42 UHMW | 42 | 3.29 (83.57) | 3.16 (80.31) | 1 (25.4) | 2.29 (58.17) |

| 5 | CTS 60-42 UHMW | 42 | 3.29 (83.57) | 3.16 (80.31) | 0.75 (19.05) | 2.29 (58.17) |

| 5 | CTS 60-42 UHMW | 42 | 3.29 (83.57) | 3.16 (80.31) | 1 (25.4) | 2.29 (58.17) |

| 6 | CTS 30-20 T303 | 20 | 3.11 (78.99) | 2.89 (73.33) | 0.69 (17.53) | 2.27 (57.66) |

| 6 | CTS 30-20 UHMW | 20 | 3.11 (78.99) | 2.89 (73.33) | 0.75 (19.05) | 2.02 (51.31) |

| 6 | CTS 30-20 UHMW | 20 | 3.11 (78.99) | 2.89 (73.33) | 1 (25.4) | 2.02 (51.31) |

| 6 | CTS 30-20 UHMW | 20 | 3.11 (78.99) | 2.89 (73.33) | 1 (25.4) | 2.02 (51.31) |

| 6 | CTS 30-20 UHMW | 20 | 3.11 (78.99) | 2.89 (73.33) | 1.75 (44.45) | 2.02 (51.31) |

| 6 | CTS 42-40 T303 SS | 40 | 4.18 (106.22) | 4 (101.5) | 0 | 3.13 (79.5) |

| 6 | CTS 42-40 T303 SS | 40 | 4.18 (106.22) | 4 (101.5) | 1 (25.4) | 3.13 (79.5) |

| 6 | CTS 42-40 T303 SS | 40 | 4.18 (106.22) | 4 (101.5) | 0 | 3.13 (79.5) |

| 6 | CTS 42-40 UHMW | 40 | 4.18 (106.27) | 4 (101.5) | 0.5 (12.7) | 3 (76.2) |

| 6 | CTS 42-40 UHMW | 40 | 4.18 (106.27) | 4 (101.5) | 1 (25.4) | 3 (76.2) |

| 6 | CTS 42-40 UHMW | 40 | 4.18 (106.27) | 4 (101.5) | 1.25 (31.75) | 3 (76.2) |

| 6 | CTS 60-54 T303 SS | 54 | 4.24 (107.82) | 4.09 (103.96) | 0.69 (17.53) | 3.23 (82.04) |

| 6 | CTS 60-54 UHMW | 54 | 4.24 (107.82) | 4.09 (103.96) | 1 (25.4) | 2.98 (75.69) |

| 7 | CTS 30-22 UHMW | 22 | 3.42 (86.77) | 3.2 (81.23) | 1.5 (38.1) | 2.33 (59.18) |

| 7 | CTS 42-56 T303 SS | 56 | 5.88 (149.28) | 5.7 (144.68) | 0 | 4.58 (116.33) |

| 7 | CTS 42-56 UHMW | 56 | 5.88 (149.28) | 5.7 (144.68) | 1 (25.4) | 4.34 (110.24) |

| 7 | CTS 60-82 T303 SS | 82 | 6.45 (163.78) | 6.32 (160.6) | 0.75 (19.05) | 5.09 (129.29) |

| 7 | CTS 60-82 UHMW | 82 | 6.47 (164.46) | 6.32 (160.6) | 0.75 (19.05) | 4.84 (122.94) |

| 7 | CTS 60-82 UHMW | 82 | 6.47 (164.46) | 6.32 (160.6) | 1 (25.4) | 4.84 (122.94) |

| 7 | CTS 60-82 UHMW Blue | 82 | 6.47 (164.46) | 6.32 (160.6) | 0.75 (19.05) | 4.84 (122.94) |

| 8 | CTS 30-24 T303 | 24 | 3.74 (95.1) | 3.54 (89.81) | 0 | 2.79 (70.87) |

| 8 | CTS 30-24 T316L | 24 | 3.74 (95.1) | 3.54 (89.81) | 0 | 2.79 (70.87) |

| 8 | CTS 30-24 UHMW | 24 | 3.74 (95.12) | 3.52 (89.51) | 1 (25.4) | 2.53 (64.26) |

| 9 | CTS 30-26 T303 | 26 | 4.07 (103.25) | 3.84 (97.64) | 0.69 (17.53) | 2.98 (75.69) |

| 9 | CTS 30-26 UHMW | 26 | 4.07 (103.25) | 3.84 (97.64) | 0.75 (19.05) | 2.85 (72.39) |

| 10 | CTS 30-30 UHMW | 30 | 4.7 (119.28) | 4.49 (114.17) | 2.76 (70) | 3.38 (85.85) |

| 10 | CTS 30-30 UHMW | 30 | 4.7 (119.28) | 4.49 (114.17) | 0.75 (19.05) | 3.38 (85.85) |

| 11 | CTS 30-40 T303 | 40 | 6.29 (159.84) | 6.09 (154.71) | 0 | 4.86 (123.44) |

Material Reference

- Acetal - polyoxymethylene plastic

- Celcon - acetal copolymer

- CI - cast iron

- Hardened Steel

- Nylon

- T303 - stainless steel

- T316 - stainless steel

- UMHW - polyethylene plastic

Nose Roll Sizing

The minimum recommended nose roll diameter for the Cleatrac® belts is 0.63" (15.9mm) for the CTB 30, 42, 48, and 60 mesh belts. Generally, use of nose rolls is not recommended with CTB 18 mesh belts.

Exception: If the application has a conveyor end-to-end distance of 10' (3 m) or less and the belt fits loosely around the conveyor, the minimum nose roll diameter may be decreased as follows:

| Mesh | Minimum Diameter in (mm) |

|---|---|

| CTB 18-16-1414 | 1 (25.4) |

| CTB 18-16-1616 | 1 (25.4) |

| CTB 30-24-1616 | 0.5 (12.7) |

| CTB 30-24-1717 | 0.5 (12.7) |

| CTB 42-36-1616 | 0.375 (9.5) |

| CTB 42-36-1717 | 0.375 (9.5) |

| CTB 42-36-1818 | 0.375 (9.5) |

| CTB 48-48-1717 | 0.25 (6.3) |

| CTB 60-48-1818 | 0.25 (6.3) |

| CTB 60-48-1820 | 0.25 (6.3) |

| CTB 60-60-1818 | 0.2 (5.1) |

| CTB 60-60-1818F | 0.2 (5.1) |

Cleatrac® Meshes

| Mesh | Thickness in. (mm) |

Lateral Pitch in. (mm) |

Opening Size (approx) |

Working Strength per Unit of Belt |

|---|---|---|---|---|

| CTB 18-16-1616 | 0.301 (7.6) | 0.67 (17.0) | 0.777 x 0.301 (inches) | 100 lb/ft (149 kg/m) |

| CTB 18-16-1414 | 0.35 (8.9) | 0.695 (17.7) | 0.855 x 0.350 (inches) | 250 lb/ft (372 kg/m) |

| CTB 30-24-1616 | 0.263 (6.7) | 0.505 (12.8) | 0.613 x 0.263 (inches) | 300 lb/ft (446 kg/m) |

| CTB 30-24-1717 | 0.287 (7.3) | 0.485 (12.3) | 0.590 x 0.287 (inches) | 200 lb/ft (298 kg/m) |

| CTB 42-36-1616 | 0.24 (6.1) | 0.35 (8.9) | 0.460 x 0.240 (inches) | 325 lb/ft (484 kg/m) |

| CTB 42-36-1717 | 0.235 (6.0) | 0.33 (8.4) | 0.435 x 0.235 (inches) | 325 lb/ft (484 kg/m) |

| CTB 42-36-1818 | 0.236 (6.0) | 0.325 (8.3) | 0.414 x 0.236 (inches) | 240 lb/ft (357 kg/m) |

| CTB 48-48-1717 | 0.24 (6.1) | 0.275 (7.0) | 0.375 x 0.240 (inches) | 450 lb/ft (670 kg/m) |

| CTB 60-48-1818 | 0.205 (5.2) | 0.26 (6.6) | 0.350 x 0.205 (inches) | 350 lb/ft (521 kg/m) |

| CTB 60-48-1820 | 0.156 (4.0) | 0.27 (6.9) | 0.326 x 0.156 (inches) | 120 lb/ft (179 kg/m) |

| CTB 60-60-1818 | 0.22 (5.6) | 0.225 (5.7) | 0.310 x 0.220 (inches) | 350 lb/ft (521 kg/m) |

| CTB 60-60-1818F | 0.22 (5.6) | 0.225 (5.7) | 0.310 x 0.220 (inches) | 350 lb/ft (521 kg/m) |

System Requirements

Application Notes

- UHMW material type components have a 150°F (66°C) maximum operation temperature.

- Molded acetal material type components have a 180°F (82°C) maximum operation temperature.

Tunnel Freezers

Use with caution as ice and snow accumulates in mesh opening or on the drive components, prohibiting sprocket teeth engagement. Install a rotary brush, or similar cleaning method, near sprocket location to minimize debris.

Soft Dough Products

Use with caution as debris may accumulate in mesh openings or on the drive components, prohibiting sprocket teeth engagement. Install a rotary brush, or similar cleaning method, near sprocket location to minimize debris.

Elevated Temperatures

Thermal expansion of the belt width may adversely affect sprocket engagement with the belt openings. If this is evident when the belt reaches application temperature, lock only the middle third of the sprockets onto the shaft so the outer sprockets can 'float' along the shaft, allowing for thermal expansion and contraction of the belt. Keep in mind that the shaft will have to be kept clean to allow sprockets to 'float'. For flour-based products in elevated temperatures, arrange the drive configuration such that a shield prevents debris from accumulating on the shaft and drive components.

Multiple Belts Driven by Common Drive Shaft

When two or more belts are driven on a common drive shaft and product alignment is critical, Ashworth Bros., Inc., must be notified at time of the purchase order is generated so that the belts will be matched. Slight differences in belt pitch can affect the alignment of the product over longer conveyor runs (typically 10ft (3m) or greater). Replacement belts for these applications require that the order reference previous purchase orders.

Number of Sprockets

The minimum number of sprockets per shaft (x) can be calculated based on the following formula:

X = Belt Width / (A + B)

Where:

A = maximum allowable spacing between sprockets

B = overall sprocket width

Fractional values should be reounded up to the next whole number.

| Mesh | (A) Max Spacing Between Sprockets in. (mm) |

Minimum Spacing in. (mm) |

|---|---|---|

| CTB 18-16-1414 | 5 (127.0) | 0.695 (17.7) |

| CTB 18-16-1616 | 5 (127.0) | 0.67 (17.0) |

| CTB 30-24-1616 | 3.25 (82.5) | 0.505 (12.8) |

| CTB 30-24-1717 | 3.25 (82.5) | 0.485 (12.3) |

| CTB 42-36-1616 | 3.5 (88.9) | 0.35 (8.9) |

| CTB 42-36-1717 | 3.5 (88.9) | 0.33 (8.4) |

| CTB 42-36-1818 | 3.5 (88.9) | 0.325 (8.3) |

| CTB 48-48-1717 | 3.25 (82.5) | 0.275 (7.0) |

| CTB 60-48-1818 | 3 (76.2) | 0.26 (6.6) |

| CTB 60-48-1820 | 3 (76.2) | 0.27 (6.9) |

| CTB 60-60-1818 | 3 (76.2) | 0.225 (5.7) |

| CTB 60-60-1818F | 3 (76.2) | 0.225 (5.7) |

Need more detailed information?

Need more detailed information?

Need more detailed information?

Options

Product Options

The Sprocket is Equally as Important as the Belt!

Manufactured in either UHMW polyethylene or T303 stainless steel, Cleatrac uses the perfect sprockets to positively drive mesh belting. Sprockets are available in a variety of sizes but special size sprockets may be manufactured to meet a customer’s needs.

Positive drive provides true belt travel and minimum terminal diameters allow close transfer of product onto and off belt. Sprockets are bored oversize to allow lateral movement on the shaft compensating for changes in belt width due to temperature.

Does this meet your project needs?

Does this meet your project needs?

Does this meet your project needs?

Let’s get started!

Let’s get started!

Let’s get started!

Downloads

Downloads

Installation Guides

Technical Bulletins

Conveyor System Review Form

Illustrations

-

Cleatrac Balanced Weave, CTB18-16-14

-

Cleatrac Balanced Weave, CTB30-24-17

-

Cleatrac Balanced Weave, CTB42-36-17

-

Cleatrac Balanced Weave, CTB48-48-17

-

Cleatrac Balanced Weave, CTB60-48-1820

-

Cleatrac Balanced Weave, CTB42-36-18

-

Cleatrac Balanced Weave, CTB60-60-18

-

Cleatrac Balanced Weave, CTB18-16-16

-

Cleatrac Balanced Weave, CTB60-48-18

-

Cleatrac Balanced Weave, CTB30-24-16

Features

CLEATRAC BELT & SPROCKET SYSTEM

CLEATRAC BELT & SPROCKET SYSTEM

CLEATRAC BELT & SPROCKET SYSTEM

EFFICIENT COST-EFFECTIVE

EFFICIENT COST-EFFECTIVE

POSITIVE DRIVE

STRAIGHT RUN

HYGENIC

THE INDUSTRY'S

TIGHTEST TRANSFER

THE INDUSTRY'S TIGHTEST TRANSFER

Ashworth’s Cleatrac® belt and sprocket system is the perfect food processing solution to accurately transfer even small products, minimize product damage, and keep your manufacturing process up and running. As the industry’s only supplier of customized conical-toothed sprockets that are perfectly matched with Cleatrac belt, Cleatrac belt and sprocket systems have a proven track record in delivering the perfect pairing.

An efficient, cost-effective solution, Cleatrac Belt & Sprockets Systems are guaranteed by Ashworth to deliver positive sprocket engagement to ensure precise product conveyance throughout the processing cycle. Cleatrac belts and sprockets are also compatible with the smallest nose bar diameters in the industry, all the way down to one-fifth of an inch (5.1 millimeters)

Ashworth’s Cleatrac® belt and sprocket system is the perfect food processing solution to accurately transfer even small products, minimize product damage, and keep your manufacturing process up and running. As the industry’s only supplier of customized conical-toothed sprockets that are perfectly matched with Cleatrac belt, Cleatrac belt and sprocket systems have a proven track record in delivering the perfect pairing.

An efficient, cost-effective solution, Cleatrac Belt & Sprockets Systems are guaranteed by Ashworth to deliver positive sprocket engagement to ensure precise product conveyance throughout the processing cycle. Cleatrac belts and sprockets are also compatible with the smallest nose bar diameters in the industry, all the way down to one-fifth of an inch (5.1 millimeters)

Eliminate Belt Wavering

Guaranteed true tracking with a positive drive sprocket system

Eliminate Belt Wavering

Guaranteed true tracking with a positive drive sprocket system

CLEATRAC BELT & SPROCKET SYSTEM

AT A GLANCE

CLEATRAC BELT & SPROCKET SYSTEM

AT A GLANCE

Minimize Product Damage:

- Guaranteed positive sprocket engagement ensures precise product conveyance

- The tightest product transfer solution in the industry

- Compatible with the industry’s smallest nose bar diameters

- Sprockets designed with conical shaped teeth have no sharp points that can damage spiral wires

- Available in various mesh configurations for precise product support and airflow for a wide range of applications

Reduce Operating Costs:

- Less expensive than chain-edge construction systems

- Engineered to deliver longer belt life than pin roll drives

- More durable and less prone to fatigue than single-plane wire designs

- Constructed with an easy-to-clean open balanced weave design

On Demand Availability:

- Standard widths are in stock and available for delivery within 24 hours

- Available complete with sprockets, support bearings, and filler rolls

DIRECTION

STRAIGHT RUN

APPLICATIONS

Durable & Energy Efficient

Withstands the toughest environments with half the mass of standard flat wire

THE SPROCKET IS EQUALLY AS IMPORTANT AS THE BELT!

THE SPROCKET IS EQUALLY AS IMPORTANT AS THE BELT!

Manufactured in either UHMW polyethylene or T303 stainless steel, Cleatrac uses the perfect sprockets to positively drive mesh belting. Sprockets are available in a variety of sizes but special size sprockets may be manufactured to meet a customer’s needs.

Manufactured in either UHMW polyethylene or T303 stainless steel, Cleatrac uses the perfect sprockets to positively drive mesh belting. Sprockets are available in a variety of sizes but special size sprockets may be manufactured to meet a customer’s needs.

Positive drive provides true belt travel and minimum terminal diameters allow close transfer of product onto and off belt. Sprockets are bored oversize to allow lateral movement on the shaft compensating for changes in belt width due to temperature.

Positive drive provides true belt travel and minimum terminal diameters allow close transfer of product onto and off belt. Sprockets are bored oversize to allow lateral movement on the shaft compensating for changes in belt width due to temperature.

Improved Can Stability

Smooth even surface for tight can transfers

Does this meet your project needs?

Does this meet your project needs?

Does this meet your project needs?

Let’s get started!

Let’s get started!

Let’s get started!

Specifications

Belt Calculator

Belt Weight

Working Strength

Opening Size

Open Area Surface

Open Area Thru

Min Nose Diameter

Thickness

Available Sprocket Options

Sprocket Reference

Select another sprocket size

Select a product

| Nom. Size | Display | Teeth | Pitch Diameter in (mm) | Hub Diameter in (mm) | Bore Min in (mm) | Bore Max in (mm) |

|---|---|---|---|---|---|---|

| 1 | CTS 18-08 T303 | 8 | 1.75 (44.42) | 1.51 (38.38) | 0 | 1.08 (27.43) |

| 1 | CTS 18-08 UHMW | 8 | 1.75 (44.42) | 1.51 (38.38) | 0.25 (6.35) | 1 (25.4) |

| 1 | CTS 18-08 UHMW | 8 | 1.75 (44.42) | 1.51 (38.38) | 0.5 (12.7) | 1 (25.4) |

| 1 | CTS 18-08 UHMW | 8 | 1.75 (44.42) | 1.51 (38.38) | 0.75 (19.05) | 1 (25.4) |

| 1 | CTS 18-08 UHMW | 8 | 1.75 (44.42) | 1.51 (38.38) | 1 (25.4) | 1 (25.4) |

| 1 | CTS 30-08 T303 | 8 | 1.15 (29.29) | 0.94 (23.8) | 0 | 0.62 (15.88) |

| 1 | CTS 30-08 UHMW | 8 | 1.15 (29.29) | 0.94 (23.8) | 0.25 (6.35) | 0.62 (15.88) |

| 1 | CTS 30-08 UHMW | 8 | 1.15 (29.29) | 0.94 (23.8) | 0.5 (12.7) | 0.62 (15.88) |

| 1 | CTS 30-08 UHMW | 8 | 1.15 (29.29) | 0.94 (23.8) | 0.5 (12.7) | 0.62 (15.88) |

| 1 | CTS 30-08 UHMW | 8 | 1.15 (29.29) | 0.94 (23.8) | 0.62 (15.88) | 0.62 (15.88) |

| 1 | CTS 42-12 T303 SS | 12 | 1.19 (30.23) | 1 (25.5) | 0.5 (12.7) | 0.63 (16) |

| 1 | CTS 42-12 UHMW | 12 | 1.2 (30.38) | 1.01 (25.73) | 0.5 (12.7) | 0.5 (12.7) |

| 1 | CTS 42-12 UHMW | 12 | 1.2 (30.38) | 1.01 (25.73) | 0.5 (12.7) | 0.5 (12.7) |

| 1 | CTS 48-20 T303 SS | 20 | 1.52 (38.73) | 1.34 (34.01) | 0 | 0.96 (24.38) |

| 1 | CTS 48-20 UHMW | 20 | 1.52 (38.73) | 1.34 (34.01) | 0.5 (12.7) | 0.72 (18.29) |

| 1 | CTS 60-08 UHMW | 8 | 0.56 (14.2) | 0.43 (11.02) | 0.24 (5.99) | 0.25 (6.35) |

| 1 | CTS 60-08 UHMW | 8 | 0.56 (14.2) | 0.43 (11.02) | 0.2 (5.08) | 0.25 (6.35) |

| 1 | CTS 60-08 UHMW | 8 | 0.56 (14.2) | 0.43 (11.02) | 0.25 (6.35) | 0.25 (6.35) |

| 1 | CTS 60-28 T303 SS | 28 | 1.73 (43.89) | 1.57 (39.95) | 0.69 (17.53) | 1.14 (28.96) |