Omni-Grid®

Select another product option

Features

Specifications

Options

Downloads

Features

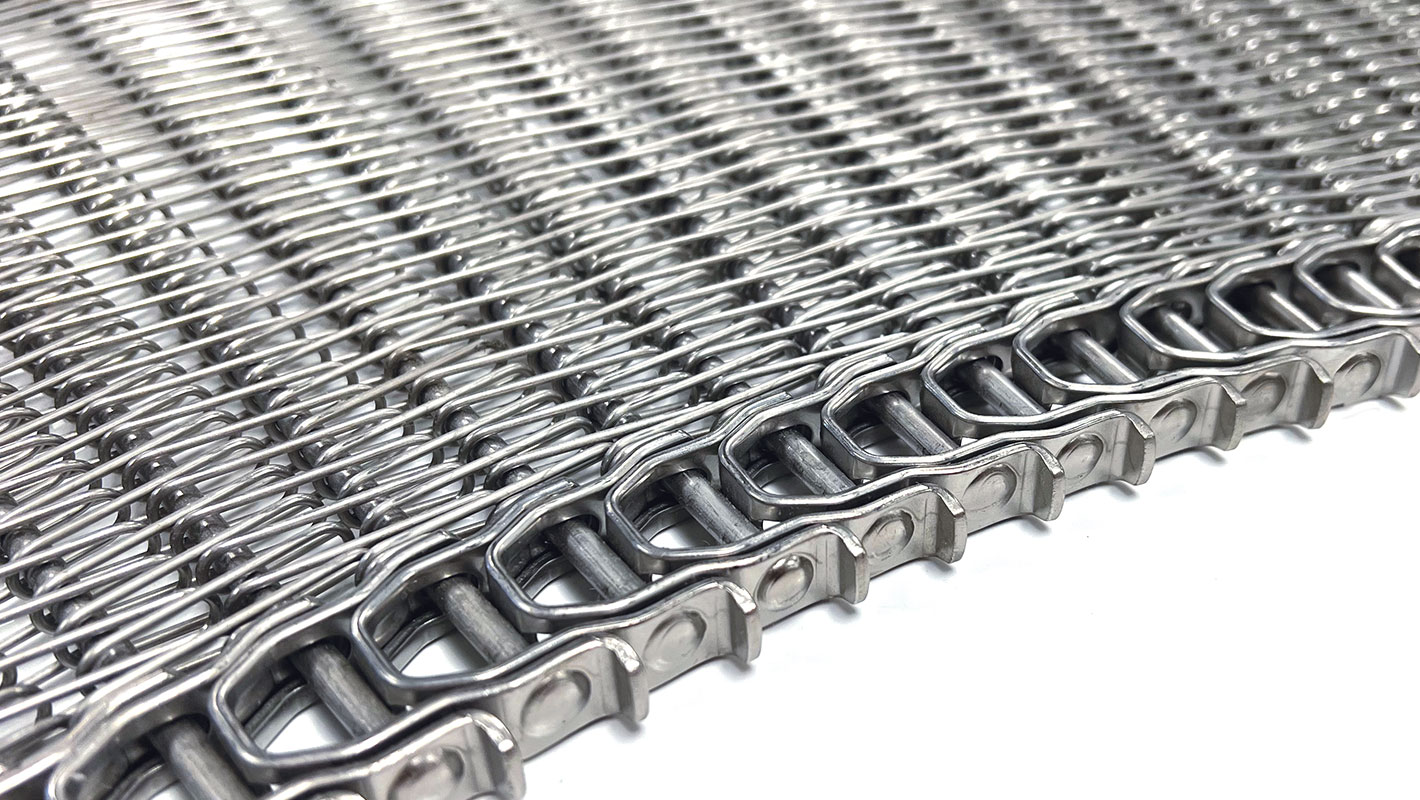

OMNI-GRID® 075 WELD

OMNI-GRID® 075 WELD

BELTS THAT RUN SMOOTHER, STRONGER, LONGER

BELTS THAT RUN SMOOTHER, STRONGER, LONGER

SPIRAL

LOTENSION

HYGENIC

Proven Reliability

All Ashworth belts are rated for 100,000 cycles versus competition ratings of only 50,000 cycles

Reduced Wear

Patented “protrusion leg” design enables the belt to run smoother with less system wear

Increased Belt Life

Patented coining feature reduces run-in wear and increases belt life

DIRECTION

APPLICATIONS

Specifications

Technical Specifications

Select another product option

| Technical Specifications | Units | OG075 |

|---|---|---|

| Turn Ratio | 2.2-2.5 | |

| Pitch | in. [mm] | 0.75 [19.0] |

| Available Widths: Curve/Spiral | in. [mm] | 6-40 [152-1016] |

| Available Widths: Straight Run | in. [mm] | 6-40 [152-1016] |

| Link Height | in. [mm] | 0.44 [11.1] |

| Rod Diameter/Material | in. [mm] | 0.192 [4.9] Metal |

| Conveying Surface | in. [mm] | Width -2.38 [-60.45] |

| Allowable Tension (Curve/Spiral) | lb. [kg] | 150 [68] at 100,000 cycles (when configured for maximum strength) |

| Allowable Tension (Straight Run) | lb. [kg] | 300 [136] at 100,000 cycles (when configured for maximum strength) |

| Turn Direction | Bi-directional | |

| Mode of Turning | Inside edge collapses in turn | |

| Method of Drive | Sprockets driven on links |

Options

Product Options

Omni-Tough Mesh Overlay

2½ times stronger than conventional

overlays and is resistant to product

sticking in freezer applications

Patented Pigtail Spirals

Reduces wear breakage

Patented Special Mesh Spirals

A cost effective solution for adding

lane dividers or flights

Does this meet your project needs?

Does this meet your project needs?

Does this meet your project needs?

Let’s get started!

Let’s get started!

Let’s get started!

Downloads

Downloads

Technical Bulletins

Conveyor System Review Forms

Illustrations

Features

OMNI-GRID® 100 WELD

OMNI-GRID® 100 WELD

BELTS THAT RUN SMOOTHER, STRONGER, LONGER

BELTS THAT RUN SMOOTHER, STRONGER, LONGER

SPIRAL

LOTENSION

HYGENIC

Proven Reliability

All Ashworth belts are rated for 100,000 cycles versus competition ratings of only 50,000 cycles

Reduced Wear

Patented “protrusion leg” design enables the belt to run smoother with less system wear

Increased Belt Life

Patented coining feature reduces run-in wear and increases belt life

DIRECTION

APPLICATIONS

Specifications

Technical Specifications

Select another product option

| Technical Specifications | Units | OG100 |

|---|---|---|

| Turn Ratio | 2.2-6.0 | |

| Pitch | in. [mm] | 1.08 [27.4] |

| Available Widths: Curve/Spiral | in. [mm] | 6-40 [152-1016] |

| Available Widths: Straight Run | in. [mm] | 6-40 [152-1016] |

| Link Height | in. [mm] | 0.50 [12.7] |

| Rod Diameter/Material | in. [mm] | 0.192 [4.9] Metal |

| Conveying Surface | in. [mm] | Width -2.44 [-61.98] |

| Allowable Tension (Curve/Spiral) | lb. [kg] | 150 [68] at 100,000 cycles (when configured for maximum strength) |

| Allowable Tension (Straight Run) | lb. [kg] | 300 [136] at 100,000 cycles (when configured for maximum strength) |

| Turn Direction | Bi-directional | |

| Mode of Turning | Inside edge collapses in turn | |

| Method of Drive | Sprockets driven on links |

Options

Product Options

Omni-Tough Mesh Overlay

2½ times stronger than conventional

overlays and is resistant to product

sticking in freezer applications

Patented Pigtail Spirals

Reduces wear breakage

Patented Special Mesh Spirals

A cost effective solution for adding

lane dividers or flights

Does this meet your project needs?

Does this meet your project needs?

Does this meet your project needs?

Let’s get started!

Let’s get started!

Let’s get started!

Downloads

Downloads

Technical Bulletins

Conveyor System Review Forms

Illustrations